FIBERS FOR COMMUNICATION: Fluorine-doped core boosts radiation resistance of single-mode fiber

SEAN FOLEY

In recent years, there has been a renewed interest in improving the radiation resistance of optical fibers. Scientists at linear accelerators and particle colliders were early initiators of these activities when they determined the need to remotely sense and relay information about high-energy particle interactions. Due to very long tunnels and high electromagnetic fields, glass optical fiber is an optimal physical medium over which to transport this information to central locations.

Nuclear power plants have increasingly deployed optical-fiber cables for IT and security networks where optical cable generally has not been exposed to high radiation levels, even under theoretical accident conditions. However, this situation is changing as existing nuclear plants shift from analog to digital control systems and new nuclear-plant designs reduce overall cabling infrastructure by taking advantage of fiber’s huge bandwidth. In these new applications, optical cable must operate reliably under radiation conditions, at least in postulated accident conditions, and even as part of normal operating conditions if it is to be used in high-radiation areas within the nuclear plant.

Radiation-induced aging

When silica-based optical fiber is exposed to radiation, various color centers are induced where there are already defects in the fiber. The formation of these color centers increases light absorption, causing attenuation to increase. This effect is known as radiation-induced aging (RIA; see “Several factors influence RIA,” below).

Because RIA for a single type of optical fiber depends on so many variables (temperature history, dose rate, total dose, and periods of low or no dose), it is difficult to reliably predict the likely condition of fiber before and after a postulated accident. Nonetheless, new developments have significantly reduced and stabilized the effects of some of the variables affecting RIA, thereby reducing the complexity of qualifying optical fibers for use in safety-related functions in nuclear plants.

New optical-fiber developments

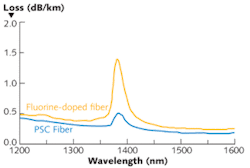

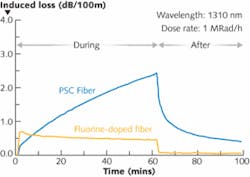

At Fujikura, we have been carrying out R&D of radiation-resistant optical fibers for more than 20 years. Typical single-mode fibers are manufactured with a germanium-doped core and pure silica cladding, whereas pure-silica-core (PSC) fibers are manufactured with a pure silica core and fluorine-doped cladding. We recently developed another option: a radiation-resistant single-mode optical fiber with a fluorine-doped core, in which the concentration of fluorine by weight is optimized to 0.8% (see Fig. 1).Researchers from CERN (Geneva, Switzerland) and the Fraunhofer Institute (Munich, Germany) evaluated fibers for potential use in the Large Hadron Collider (Geneva) and identified Fujikura’s fiber as being most suitable.1 The study identified two key capabilities of Fujikura’s new fiber. First, at 1310 nm, induced transmission losses did not exceed 5 dB/km at dose rates up to 1 MRad per hour. In the same study, the next-best-performing fiber exhibited induced losses of about 18 dB/km. Second, at high doses, the induced loss saturated, thus becoming independent of the total accumulated dose. Most other fibers continued to show increasing RIA for long periods after Fujikura’s fiber had stabilized.

Another notable point from the study was how the new fiber compared with PSC fibers. In a screening test performed at a dose rate of 72 KRad/h, the best PSC fiber exhibited RIA that was two to six times higher than Fujikura’s radiation-resistant single-mode fiber at intermediate doses. Germanium-doped fibers exhibited losses that were an order of magnitude higher than Fujikura’s fiber (see Fig. 2).Applicability to the resurging nuclear industry

The development of radiation-resistant single-mode fibers seems very useful to long linear accelerators, but could the fiber be useful for smaller-scale nuclear generating stations?

In nuclear facilities, single-mode fiber is typically used for networking or security to connect buildings in the power-plant complex or for security networks. Sometimes, it is used for supervisory control and data-acquisition applications connecting substations. Most of these applications do not involve nuclear-power-plant safety or radiation exposure, even in the case of a theoretical accident.

In typical industrial Ethernet or premise applications, data from many ports are aggregated in a switch or programmable logic controller (PLC) and then uplinked to a server, or connected in a daisy chain with other switches. The switch or PLC can have a built-in fiber uplink or it can be connected to the network through a media converter that converts the electrical signal to an optical signal. The optical medium for these inside plant applications is often a multimode fiber, especially when the link distance is less than 1000 ft.

The inside-plant preference for multimode fiber is driven by overall link costs. The cost of an optical link includes the transceiver costs, connection costs, and the cost of the optical cable. Single-mode fiber-optic cabling is usually less expensive than multimode fiber-optic cabling, but transceivers designed to work with single-mode fiber can be 50% to 200% higher in price than multimode transceivers. For short distances, the higher transceiver costs often outweigh the lower price of single-mode fiber-optic cable.

The shift to digital control systems and the advent of new plant designs require significantly more attention to the potential impacts of radiation on optical fiber and reliability. A dependable form of radiation-resistant single-mode fiber could be the best choice, even for short-link applications, for a number of reasons.

First, digital controls for nuclear plants are expected to use 100 Mbit/s Ethernet-based electronics over fiber, which have a much smaller dynamic range than currently “qualified” analog transmitters and receivers. This means that the allowable increase in attenuation due to environmental factors must be much smaller, which limits either the distance before the signal has to be repeated or the potential radiation levels the cabling system can be used in.

Second, off-the-shelf 100 Mbit/s Ethernet transceiver modules, either multimode or single-mode, are relatively inexpensive because of economies of scale. The high cost to qualify Ethernet electronics for safety-related functions and/or the cost to shield transceivers from radiation will quickly equalize the end user’s costs for either type of transceiver, leaving cable and connection costs as the major cost differentiator. In this case, the fiber of choice is likely to be single-mode due to its higher bandwidth, lower induced attenuations, and lower cost.

Third, in nuclear safety, reliability is king. Our radiation-resistant single-mode fiber provides a level of stability and consistency in radiation environments that is not equaled by previous optical fibers.

Fourth, many nuclear facilities prefer to buy a single type of cable for both safety-related (instrumentation and control) and non-safety-related functions (security and video). For some facilities, multimode fiber might not have the combined bandwidth and reach to enable high-quality video-surveillance applications. Perimeter security systems deployed on fences are migrating toward vibration-based sensing, which also relies on the unique characteristics of single-mode optical fibers.

Finally, new plants have a design life of 60 years. The bandwidth of single-mode fibers supports at least two to three orders of magnitude in scalability beyond the intended 100 Mbit/s systems of today.

Adopting the technology

Use of fiber-optic cabling for safety-related functions within nuclear facilities is no longer a pipe dream. At least one reactor-plant vendor intends to use optical cable as the main communication medium between its main control station and the rest of the power plant in new reactor designs. IEEE (New York, NY) has a working group which is drafting a standard for qualification of Class 1E fiber-optic cables and components in nuclear power plants.

There is still some way to go before fiber-optic cabling is fully adopted into the nuclear industry. Not only must standards be completed, but cable and electronics must be developed and qualified, not just for potential high radiation levels, but also for a 60-year life. Due to optical fiber and cabling developments for harsh environments, that goal no longer seems impossible to meet. Even the use of optical cabling for “in-containment” applications, which include potential exposure to extreme temperatures, pressure, and chemical spray, is within the realm of possibility.

REFERENCES

- T. J. Wijnands et al., Topical Workshop on Electronics for Particle Physics 2007, p.121 Sept. 2007.

- K. Aikawa et al., Fujikura Tech. Rev., 2008, p. 9.

Sean Foley is a market development manager at AFL Telecommunications, 260 Parkway East, Duncan, SC 29334. AFL Telecommunications is a Fujikura business; e-mail: [email protected]; www.afltele.com.