Though their methodologies and competitive strategies differ–SunPower focuses on high conversion efficiency, while Suntech focuses on lower cost–these two companies are threatening other established players and even thin-film competitors with their crystalline-silicon photovoltaics.

STEVE EGLASH

It seems like only yesterday that solar-cell manufacturers were racing to increase production capacity as quickly as possible. Demand for solar cells exceeded supply and even second-tier manufacturers could sell everything they could make. Capital for solar energy installations–and for expanding solar-cell factories–was abundant and cheap. All of that has recently changed, but not necessarily to the long-term detriment of the solar industry.

The perfect storm of factors driving demand for renewable energy has moderated. Oil is selling at half its peak price. Governments remain concerned about global warming, pollution, and energy self-sufficiency, but they have scaled back support for the feed-in tariffs, incentives, and subsidies that helped to prop up demand for solar and wind power. The predictable result is excess supply and falling prices.

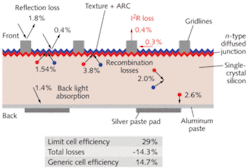

FIGURE 1. A generic solar cell has multiple loss mechanisms (losses shown are a percentage of the incident radiation). This device exhibits an efficiency of 14% to 15% and was the mainstay of the solar industry for several years. (Courtesy of SunPower)

Manufacturers of solar cells now find themselves in a competitive market, some for the first time in their corporate lives. Some are fighting for their very survival. The strongest companies are using the worldwide recession to position themselves for even greater success as the economy recovers. Two industry leaders—SunPower (San Jose, CA) and Suntech Power Holdings (Wuxi, China)—are taking very different yet equally successful paths to increase their competitive advantage.

The value proposition

Each of these winning approaches requires the application of materials science, semiconductor device physics, and manufacturing engineering to implement the best high-efficiency solar-cell designs in a mass-production environment at the lowest cost. SunPower produces photovoltaic (PV) modules with a conversion efficiency of 20% from single-crystal Czochralski silicon—the highest efficiency in the industry. Suntech produces modules from multicrystalline cast silicon with an efficiency of 16.5% at an astonishingly low cost of $1.50 per watt (Suntech has also produced modules from single-crystal Czochralski silicon at 18% efficiency).

These benchmarks are squeezing manufacturers throughout the PV industry. Manufacturers with higher cost structures must figure out how to reduce costs. Thin-film PV manufacturers have to increase conversion efficiency while maintaining their advantage of lower cost. Manufacturers of concentrated photovoltaics (CPV) need to increase efficiency and decrease costs to achieve a competitive cost per watt.

With SunPower’s no-compromise approach to achieving maximum conversion efficiency, and with Suntech’s relentless balance of high efficiency and low cost, both companies have managed to achieve record solar-cell efficiency, module cost, or cost of energy. Much can be learned by studying their individual methodologies and competitive strategies.

The highest efficiency

The conversion efficiency of a solar cell is limited by optical absorption, carrier transport, and carrier collection. For a silicon solar cell the maximum theoretical efficiency is 29%, limited by losses due to the excess energy of above-bandgap photons, transparency to photons below the bandgap, and radiative and Auger recombination. In practice, solar cells exhibit a much lower efficiency due to additional losses. It is only by understanding and reducing these losses that more-efficient solar cells can be developed.

For many years the efficiency of commercially available wafer-based silicon solar cells was stagnated at 14% to 15%. The industry manufactured a “generic” solar cell with multiple loss mechanisms: a 3.6% efficiency loss from incident solar radiation either reflected at the front surface or absorbed unproductively at the back contact; a 2% loss due to bulk recombination of carriers; and another 8.6% loss from recombination at the contacts and resistive loss (see Fig. 1). The 29% efficiency potential is thus reduced to below 15% in a standard silicon cell.

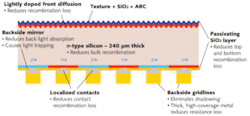

FIGURE 2. SunPower’s backside contact cell is the result of implementing a wide range of high-efficiency concepts in a high-volume process to achieve a cell efficiency of 24%. (Courtesy of SunPower)

A number of high-efficiency concepts were developed to reduce these losses and more closely approach the 29% ideal. Although researchers have since applied these concepts to achieve an efficiency of 25% in laboratory-scale devices, the challenge is to engineer solutions that can be implemented at low cost on high-volume production lines.

An alloyed aluminum p-type back-surface layer reduces the recombination of electrons at the back contact. The use of a silicon nitride front-surface antireflection coating in place of titanium dioxide (TiO2) results in reduced recombination at the top surface. Selective-emitter technology is used to dope the top junction more heavily under the metal contacts, which results in lower series resistance and avoids creating a dead layer between the contacts where the light is absorbed. Laser processing can be used to create selective-area back contacts, thus reducing carrier recombination at the back surface.

In the SunPower solar cell, all contacts are moved to the back to maximize light transmission into the cell and reduce carrier recombination at the front surface (see Fig. 2). Lightly doped front diffusion, backside mirror, and silicon dioxide (SiO2) passivation layers are all used to reduce losses. The proper design of such a structure is not trivial and requires sophisticated modeling of two-dimensional carrier transport and careful control of carrier recombination. SunPower’s execution favors high efficiency, even if it involves using more expensive manufacturing processes.

The advantages of high efficiency ripple through the entire renewable-energy value chain. The efficiency of a solar cell determines the amount of energy that can be generated per unit area of real estate. That area has value whether it is a residential roof, a commercial roof, or a utility-scale solar farm. A facility using higher-efficiency solar cells will produce more electricity and result in a better return on investment. Furthermore, the cost of installing a solar panel is the same regardless of the efficiency of the solar cells. High-efficiency solar cells are therefore less expensive to install on a cost-per-watt basis.

The lowest cost per watt

Suntech has taken a decidedly different approach. Historically Suntech has focused on achieving the lowest manufacturing cost per wafer by emphasizing process development, manufacturability, yield, uniformity, and reproducibility. But cost and efficiency must both be optimized to achieve the lowest cost per watt or cost per kilowatt-hour. Six years ago Suntech launched a collaboration with the University of New South Wales (UNSW; Sydney, Australia). The UNSW had achieved record efficiencies in laboratory-scale devices. Suntech wanted to know whether the high-efficiency concepts from UNSW could be applied to high-volume production at Suntech without adding significant cost.

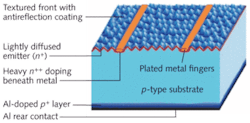

FIGURE 3. Suntech’s high-efficiency and low-cost cell is based on the record-setting PERL cell developed at the University of New South Wales. This device incorporates front metal lines less than 25 µm wide and screen-printed and fired rear aluminum contacts. (Courtesy of Suntech)

The answer turned out to be yes, but it would take a major effort. The PERL (passivated emitter and rear locally diffused) solar cell developed at UNSW has exhibited an efficiency of 25%–a world record for a silicon solar cell at standard illumination conditions. However, this device requires expensive materials and complex processes that make it prohibitively expensive to manufacture in volume. To transfer high-efficiency concepts to a high-volume and low-cost manufacturing line, engineers would need to consider the cost and benefit of each material and process, and they would have to develop new processes. The result of this effort is the current-production Suntech solar cell (see Fig. 3).

The type of silicon wafer, the technique used for front-surface texturing, and the antireflection coating all affect the efficiency of the solar cell, but the effects are not independent. To achieve the optimum balance, Suntech applied a sophisticated understanding of the tradeoffs and interactions between these materials and processes: the PERL cell uses float-zone wafers, which are more expensive than multicrystalline wafers. Relative to float-zone wafers, multicrystalline wafers exhibit a lower minority carrier lifetime, increased bulk recombination of carriers, and lower open-circuit voltage and short-circuit current. Suntech decided to use multicrystalline wafers, despite the drop in solar-cell efficiency.

Front-surface texturing is used to reduce reflection in most modern solar cells. The PERL cell uses photolithographic texturing, but this was deemed too expensive for the Suntech cell. Suntech developed a new low-cost texturing process that actually works better than the photolithographic process. The texturing process allowed them to replace the expensive double-layer antireflection coating used in the PERL device with a lower-performance coating composed of a single layer of silicon nitride, without any overall decrease in light transmission. The antireflection coating also affects the surface recombination velocity. Suntech’s new textured and silicon-nitride-passivated surface exhibits increased carrier recombination. Although the difference would have been significant with float-zone wafers, it was negligible with multicrystalline wafers.

Cell performance can also be improved through the use of selective-emitter technology. The PERL cell uses photolithography, expensive titanium/palladium/silver metallization, and thermal oxidation to achieve narrow metal lines that exhibit low resistance and are aligned with n+ semiconductor contact layers. High-volume production lines typically use screen printing. The spatial resolution of screen printing is inferior to photolithography, resulting in unfortunate tradeoffs that result in increased reflection from metal lines, increased resistive loss, or both. Suntech developed a new printing and plating technique that produces 25-µm-wide and 10-µm-high metal lines, resulting in minimal front-surface reflection and adequate cross section for low-resistance current flow.

The net effect is a process that can be retrofitted onto existing screen-printing production lines with only a modest capital expense. The device exhibits a 10% to 15% improvement in conversion efficiency with no increase in manufacturing cost per wafer.

The future

SunPower and Suntech are important examples of a broader trend. Innovation will continue to create important technologies and dominant companies as it has in SunPower’s case. SunPower created the modern PV market and continues to lead and play a dominant role. The industry is seeing similar innovation and leadership from thin-film PV companies that are achieving efficiencies of 12% to 14% and greater, manufacturing costs below $1/W, and the potential for deployment of lightweight and flexible form factors.

Suntech has achieved superior performance at an industry-leading low cost, resulting in the lowest cost per watt for a high-efficiency solar panel. No company and no geographic region has a monopoly on innovation. Smart engineers are everywhere and, just like similar trends in consumer electronics and automobiles, high-efficiency concepts will be incorporated in low-cost manufacturing lines. The future is very bright for PV companies that continue to push the envelope of efficiency, manufacturing cost, or ease of installation.

ACKNOWLEDGMENTS

Helpful discussions with Richard Swanson and Stuart Wenham are gratefully acknowledged.

Steve Eglash has been CEO of a solar-cell company and a consultant to the National Renewable Energy Laboratory and the U.S. Department of Energy; 625 Glenbrook Drive, Palo Alto, CA 94306; e-mail: [email protected].

Tell us what you think about this article. Send an e-mail to [email protected].