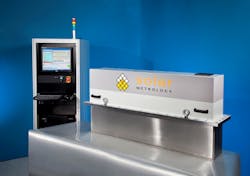

Solar Metrology CIGS measurement tool for in situ x-ray fluorescence

System SMX-Linear ISI is an in situ x-ray fluorescence metrology tool that provides cross-web or cross-panel gradient measurement of CIGS composition and thickness measurements for thin-film photovoltaic metal film stacks on flexible roll-to-roll substrates such as stainless steel, aluminum, and polyimide or rigid substrates such as float glass.

Solar Metrology

Holbrook, NY

[email protected]

-----

PRESS RELEASE

August 2010

For Immediate Release

In-Situ XRF Yield Management tool for CIGS Composition and Thickness Measurement

HOLBROOK, NY, - August 2010– Solar Metrology, a global provider of X-Ray Fluorescence (XRF) analysis tools, expands its SMX XRF tool portfolio for film composition and thickness measurement of CIGS photovoltaic depositions with the addition of the System SMX- LINEAR ISI.

Solar Metrology’s System SMX-Linear ISI is in-situ x-ray fluorescence (XRF) metrology tool platform that provides Cross Web or cross panel gradient measurement of CIGS composition and thickness measurements for thin film solar PV metal film stacks on flexible roll to roll substrates such as stainless steel, aluminum and polyimide or rigid substrates such as float glass.

Typical measurement applications include Mo thickness and all CIGS combinations (including all CIG alloys and/or film combinations and final CIGS formulations).

SMX LINEAR ISI is fast, flexible and easily integrated into any vacuum deposition tool or vacuum process station or point of a vacuum process line.

SMX LINEAR ISI utilizes X-ray fluorescence, an enabling technology for CIGS manufacture, that delivers yield management and yield improvement by allowing in-situ process control. The SMX LINEAR ISI tool Platform does not affect the deposition process since all SMX LINEAR ISI tool components reside outside of vacuum for optimum performance and serviceability.

Solar Metrology's SMX Measurement tool platform provides a production-ready suite of film thickness and composition measurement tools for research and process development, in-process monitoring and post-process quality control.

Solar Metrology is the global leader in the development and manufacture of high-performance X-Ray Fluorescence (XRF) analysis tools, specifically engineered to meet the demanding thin film measurement requirements of the solar electric and renewable power industries.

Additional information on Solar Metrology can be found at http://www.solarmetrology.com or [email protected].

-----

Subscribe now to Laser Focus World magazine; it's free!