CHILLERS: Cryogenic cooling of optical systems takes many forms

LUKE MAURITSEN and BRIAN SMITHGALL

Scientists seeking to observe subtle phenomena often find their sensitive measurements limited by noise. Temperature in materials can be thought of as a measure of the random movement of molecules, which increases at higher temperatures. This causes an uncertainty in the measurement of material properties. For example, electronic noise, also known as Johnson noise, is proportional to temperature and is attributed to the thermal excitation of electrons in a conductor. Noise can also come from other sources such as spontaneous emissions or dipole fluctuations. Noise can be described as intensity noise, phase noise, timing jitter, or spin noise.

Benefits of cooling

These random variations can often be dramatically reduced by lowering the temperature of the material. The power in Johnson noise is proportional to the temperature; dropping the temperature of a system from 300 K to 3 K can make a tremendous difference in detection limits. For example, lowering the temperature enhances the intensity in some Raman experiments because there is less intensity loss to the anti-Stokes transition from the excited state.

Low temperatures slow chemical reactions that are too fast to observe at room temperature. Molecules align or behave differently at low temperatures. Substantially improved signal-to-noise ratios are possible, which can be critical not only to discovering subtle phenomena but also creating phenomena that only exist at low temperatures. At temperatures below 5 K, for example, the atoms in some optical-memory materials will remain in a coherent excited state for very long periods of time, allowing large amounts of information to be retained in the material.

Cooling technologies

Customarily, engineers have improved the performance of imaging systems by using Peltier or thermoelectric (TE) coolers.

Classic TE coolers use a solid-state semiconductor device that transfers heat from one side of the device to the other side against the temperature gradient. Simply connecting it to a DC voltage will cause one side to cool while the other side warms. Common TE coolers can cool to about -60°. Additionally, there are other approaches that provide cooling beyond the capabilities of TE technology.

In a short-term experiment where gases may be vented, liquid nitrogen or liquid helium are often used. These provide temperatures of 77 K and 4.2 K, respectively. Liquefied gases are not practical for many applications, and liquid helium is becoming increasingly expensive in many parts of the world.

Other cooling technologies rely on various mechanical refrigeration cycles to provide cooling. These "closed-cycle" systems do not require liquid cryogens and include Stirling, Gifford-McMahon, and Joule-Thomson coolers. They have been used in many optical systems and can achieve temperatures of 3 K to 30 K, depending upon the cycle. If not implemented properly, however, they may introduce noise due to vibrations and temperature fluctuations.

Pulse-tube cryocooler technology emerged largely in the early 1980s along with other innovations in the broader field of thermoacoustics. In contrast with other cryocoolers (for example, the Stirling and Gifford-McMahon coolers), the pulse-tube cryocooler can be made with no moving parts needed in the low-temperature portion of the device. However, while capable of achieving very low temperatures, even pulse-tube cryocoolers can introduce vibrations. Even colder temperatures are possible with more exotic magnetic, helium-3, or laser-based cooling approaches.

Applications

The following are just a few examples of applications in the areas of spectroscopy and microscopy that can benefit from cooling techniques.

Cooling to cryogenic temperatures is essential for studying fundamental properties of nanostructures such as quantum dots. In one example, a photoluminescence study was done on a pair of quantum dots at a temperature of 10 K; the assembly of many optical energy spectra acquired under different applied electric fields reveals avoided crossings between spectral lines associated with a neutral (X0) or positively charged (X+) pair of quantum dots (see Fig. 1). These avoided crossings are the key signature of a charged particle existing in both dots at the same time. The anti-crossings are a signature of the coherent tunneling of a charge (in this case, a hole) between the two quantum dots making up the quantum-dot "molecule." Narrow spectral lines are required to resolve such small (or smaller) features in the energy spectrum of nanostructures. A "slice" can be taken through the intense spectral line associated with the neutral quantum-dot pair, showing that, because cooling results in very narrow spectral lines, even the distinction between two polarization components—πX and πY—is enabled.1,2

Spectroscopy research fields including Raman and Mossbauer spectroscopy also benefit from low temperatures. Spectroscopic work is helping to understand the nature of carbon nanotubes (CNTs) and graphene. In one experiment, the Raman shift between room temperature and low temperature (4.2 K) for the G-band spectra in CNTs reveals the stretching of the inter-carbon bonds and their dependence on temperature (see Fig. 2).3Implementing cryogenics

Low temperatures can open doors to breakthroughs in materials research and system developments. Incorporating these as part of active R&D work has historically been a challenge. If the temperature range of TE coolers is sufficient, they can often be incorporated very easily.

For lower temperatures, using liquid nitrogen or helium cooling can be tricky for the novice and time-consuming and expensive for the expert. Even closed-cycle systems that don't require liquid cryogens involve a concert of coordination of items such as flows and pressures for transfer cooling, avoiding condensation problems, thermal shorts, vibration isolation, and thermal stability.

Recently, instrumentation providers have developed automated closed-cycle systems to avoid these implementation obstacles. Solutions range from simple temperature controllers to integrated solutions that isolate vibrations and manage temperature accurately. As these technologies are adopted, scientists and engineers can more easily use cryogenics to eliminate noise and achieve better results.

REFERENCES

1. M. Scheibner et al., Nature Phys., 4, 291 (2008).

2. M. Scheibner et al., Solid State Communications, 1427 (2009).

3. Attocube Application Labs (2010).

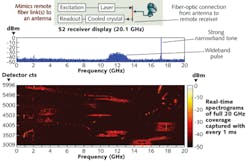

4. R. Babbitt, Spectrum Labs (2010).

Luke Mauritsen and Brian Smithgall are at Montana Instruments, 2317 Birdie Drive, Bozeman, MT 59715; e-mail: [email protected];www.montanainstruments.com.

![FIGURE 1. Optical energy spectra taken as a function of applied electric field reveal tunneling of a charge between two quantum dots (a). A slice (b) through the intense spectral line (red dash on left) is associated with the neutral quantum dot pair; two polarization components, πX and πY, can be distinguished [1,2]. FIGURE 1. Optical energy spectra taken as a function of applied electric field reveal tunneling of a charge between two quantum dots (a). A slice (b) through the intense spectral line (red dash on left) is associated with the neutral quantum dot pair; two polarization components, πX and πY, can be distinguished [1,2].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/pennwell.web.400.137.png?auto=format,compress&fit=fill&fill=blur&q=45?w=250&width=250)

![FIGURE 2. Carbon-nanotube spectra taken at 300 K and 4.2 K show stretching of the inter-carbon bonds and its dependence on temperature [3]. FIGURE 2. Carbon-nanotube spectra taken at 300 K and 4.2 K show stretching of the inter-carbon bonds and its dependence on temperature [3].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2016/01/pennwell.web.400.283.png?auto=format,compress&fit=max&q=45?w=250&width=250)