SECOND-HARMONIC GENERATION: Multicrystal scheme yields 56% efficient SHG to green

Due to the absence of suitable laser materials in the green wavelength range, second-harmonic generation (SHG) of near-infrared (IR) solid-state lasers near 1 μm has evolved as a viable technique for green generation. In continuous-wave (CW) mode, because of very low nonlinear gain, the most practical approaches for SHG have relied on intracavity or resonant enhancement techniques.

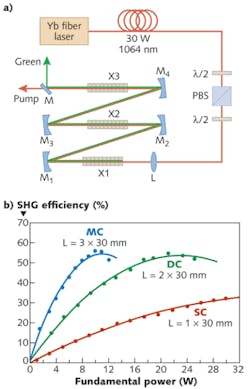

External single-pass SHG (SP-SHG) in quasi-phase-matched (QPM) single crystals has been shown to provide a simple and low-cost technique for CW SHG, with optical-to-optical conversion efficiencies up to 35%. Now, researchers at the Institute of Photonic Sciences (ICFO) and the Catalan Institute of Research and Advanced Studies (ICREA), both in Barcelona, Spain, have demonstrated 56% efficiency for a range of input power levels for SP-SHG of green light using a cascaded multicrystal scheme.1 The technique uses three identical QPM crystals of the same magnesium-oxide-doped stoichiometric periodically poled lithium tantalate (MgO:sPPLT), and the same 1064 nm CW ytterbium (Yb) fiber laser used to obtain the previous 35% efficiency with a single crystal at the highest input power.

Three crystals

The Yb fiber laser used in the experimental setup delivers up to 30 W singlemode power with a beam quality M2 >1.01, linewidth of 89 kHz, and power stability of 0.5% over 10 hr. At the output of the fiber laser are three temperature-stabilized (±0.1°C), 30 mm long crystals in a cascade, antireflection-coated to transmit > 99.5% of the input 1064 nm radiation and >99% of the generated 532 nm radiation.

In the multicrystal optical arrangement, the fundamental beam emitted from the fiber laser propagates in free space, and is focused to a 31 μm beam radius within the first crystal (see figure). This radius is close to optimum for SHG. Two mirrors then direct and focus the SHG and fundamental beam to a 46 μm beam radius within the second crystal, and the process is repeated, producing a 40 μm beam radius for the SHG within the third crystal. The fundamental beam is not focused to its optimum beam waist radius in the second and third crystals to avoid optical damage. Mirrors were used to ensure perfect mode-matching for the fundamental and SHG beams and also to minimize the relative phase shift in the two beams between successive crystals. A dichroic mirror separates the fundamental and SHG green output beams.

In addition to measuring efficiency value versus fundamental power for the SHG green light generated in the multicrystal scheme, efficiency values were recorded in a typical single-crystal and dual-crystal scheme. Maximum efficiency of 56% was obtained for the multicrystal scheme at a fundamental input power level of 10 W, providing ~5.6 W of green power.

Experiments confirmed that efficiency decreases at fundamental power levels above 10 W due to pump depletion and backconversion, not thermal dephasing. The flexible technique allows independent focusing, mode matching, and temperature control for each crystal stage.

"In principle, it would be intuitive to use increasingly longer crystals for higher CW SHG efficiency," says Majid Ebrahim-Zadeh, ICREA professor and ICFO group leader. "But the thermal dephasing effect along the length of the crystal limits the maximum efficiency. By deploying several crystals of shorter length in a multicrystal scheme, we can compensate for thermal dephasing by distributing the heat among the different crystals, while maintaining the highest conversion efficiency and beam quality. The technique is generic and can be deployed for efficient SP-SHG of CW laser sources in other spectral regions, at low powers, and using alternative QPM materials."

REFERENCE

1. G.K. Samanta et al., Opt. Lett., 35, 20, 3513-3515 (Oct. 15, 2010).

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.