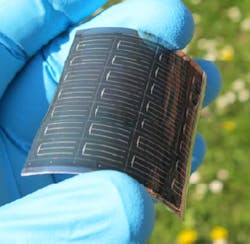

Dübendorf, Switzerland--Fabricating thin-film photovoltaic (PV) cells on flexible plastic sheets has the advantage of light weight, portability, and much easier installation when compared to the more-usual glass panels. However, the conversion efficiency of plastic thin-film PV panels is lower than that of glass. But scientists at Empa (the Swiss Federal Laboratories for Materials Science and Technology) have narrowed the efficiency gap between flexible plastic and rigid glass thin-film PV panels.

They have boosted the energy-conversion efficiency of flexible solar cells made of copper indium gallium (di)selenide (also known as CIGS) to a new world record of 18.7% (a significant improvement over the previous record of 17.6%, which was achieved by the same team in June 2010). The measurements were independently certified by the Fraunhofer Institute for Solar Energy Systems (Freiburg, Germany).

"The new record value for flexible CIGS solar cells of 18.7% nearly closes the 'efficiency gap' to solar cells based on polycrystalline silicon (Si) wafers or CIGS thin film cells on glass," says Ayodhya Tiwari, the project leader.

One major advantage of flexible high-performance CIGS solar cells is the potential to lower manufacturing costs through roll-to-roll processing. The new results suggest that monolithically interconnected flexible CIGS solar modules with efficiencies above 16% should be achievable with the recently developed processes and concepts.

Working closely with scientists at FLISOM (an Empa-affiliated start-up company that is scaling up and commercializing the technology), the Empa team made progress in low-temperature growth of CIGS layers grown on polymer or metal foil. The latest improvements in cell efficiency were made possible through a reduction in recombination losses by improving the structural properties of the CIGS layer and a low-temperature deposition process for growing the layers, as well as in situ doping with sodium during the final stage. With these results, polymer films have for the first time proven to be superior to metal foils as a carrier substrate for achieving highest efficiency.

Subscribe now to Laser Focus World magazine; it’s free

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.