TUNABLE LASERS: 760 kHz OCT scanning possible with MEMS-tunable VCSEL

Microelectromechanical systems (MEMS)-tunable vertical-cavity surface-emitting lasers (VCSELs) would be ideal for swept-source optical-coherence tomography (OCT) applications due to their micron-scale cavity length and low mirror mass for high sweep speeds, singlemode operation without mode hops, and long dynamic coherence length for long imaging range. But while MEMS-tunable VCSELs also offer wafer-scale fabrication and testing and correspondingly low-cost operation, their output power and tunability have been limited, with a 65 nm tuning range at 1550 nm the best previous performance.

Fortunately, scientists at Praevium Research (Santa Barbara, CA), Thorlabs (Newton, NJ), Advanced Optical Microsystems (AOMicro; Mountain View, CA), and the Massachusetts Institute of Technology (MIT; Cambridge, MA) have improved this scenario by developing a 1310 nm singlemode MEMS-tunable VCSEL with a 110 nm tuning range, an approximate factor-of-two improvement in fractional tuning range (Δλ/λ). The new, broadly tunable source achieved a record 760 kHz axial scan rate and uses optical amplification to achieve 40 mW average power output, opening new applications for swept-source OCT.

Singlemode operation and MEMS tuning

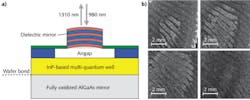

The tunable VCSEL is constructed by bonding a wide-gain, indium phosphide (InP)-based quantum-well active region to a gallium arsenide (GaAs)-based oxidized mirror. An electrostatically actuated dielectric mirror suspended over the top of this structure and separated by an air gap moves to generate 1310 nm tunable emission as the device is pumped by a 980 nm laser source (see figure). The emission is then coupled to a broadband semiconductor optical amplifier, which not only increases output power but also shapes the spectral output of the tunable VCSEL before it is input to an OCT system.

For ultrahigh-speed imaging at 760 kHz with axial scanning, a 6 dB rolloff is observed at a 4.5 mm imaging depth, corresponding to a minimum 9 mm coherence length for the tunable VCSEL, limited by measurement bandwidth. At slower imaging rates of 150 kHz with axial scanning, a coherence length of more than 25 mm has been experimentally measured. Imaging speed and range are significantly better than other swept laser sources. Because VCSELs operate in true single longitudinal mode rather than a set of modes, they can sweep at adjustable repetition rates while maintaining superior coherence length.

“Singlemode, high-speed swept sources are very promising for the next generation of OCT,” says James Fujimoto, professor of electrical engineering at MIT. “These light sources offer record imaging performance and can enable a range of new applications and markets.”

REFERENCE

1. V. Jayaraman et al., 2011 Conf. on Lasers and Electro Optics (CLEO), postdeadline paper PDPB2, Baltimore, MD (May 2011).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.