TUNABLE SOURCES: Tunable organic semiconductor lasers: Ready for the market?

Recent advances in DFB organic semiconductor lasers have overcome material limitations and taken advantage of emission efficiency and superior stability to target applications for optical transmission spectroscopy and laser-induced fluorescence.

SÖNKE KLINKHAMMER, THOMAS WOGGON, and ULI LEMMER

Since the first demonstration of laser activity in organic semiconductors in 1996, a lot of attention and work has been devoted to the exploration of suitable materials and device structures. Lasers made of organic semiconductors offer the potential of broad tuning ranges in the visible spectrum along with high efficiencies. Furthermore, the simple processing, fabrication, and the low costs render this approach very interesting for applications.

Organic light-emitting diodes (OLEDs) have successfully entered the mass market with active matrix displays (AMOLEDs) for mobile phones being the main application. While considerable effort has been devoted to the realization of an organic injection laser, such devices have not been successfully demonstrated so far. This is mainly due to the comparably poor charge-transport characteristics resulting in high free-carrier densities that are needed to maintain the current densities. In turn, this leads to optical losses by free carrier absorption. Moreover, the accumulation of triplet states and electrode-related losses has prevented injection lasing thus far.

For many applications, however, optical pumping using low-cost light sources is attractive. As shown recently by several groups, the laser thresholds have been reduced so much that compact inorganic, ultraviolet- (UV) or blue-emitting laser diodes, or even LEDs are suitable pump sources.1-5

Potential and challenges

Organic materials can show high photoluminescence quantum yields of well over 50% and they can exhibit very high gain coefficients of several thousands cm-1 upon optical pumping. Similar to the case of dye lasers, the vibrational sidebands lead to a four-level system enabling low laser thresholds.

The deposition process for the organic semiconductor layer depends on the type of the employed organic material. In general, organic semiconductors can be grouped into two classes: small molecules being deposited in vacuum, and conjugated polymers or dendrimers, which can be processed from solution. Both classes of materials have been successfully used to realize low-threshold lasers.

Very compact and efficient laser devices can be realized using a distributed feedback (DFB) geometry. A periodic, wavelength-scale corrugation of the refractive index in a slab waveguide leads to Bragg scattering and hence to the formation of laser modes. The approximate laser wavelength λLas is given by the Bragg condition as mλLas ≈ 2neffΛ with m describing the order of the diffraction and Λ being the period of the corrugation.

The effective refractive index neff of the waveguide mode depends on the refractive indices of all layers in the slab waveguide and their respective thicknesses. For m = 2 the laser radiation in the waveguide is coupled out of the film surface perpendicular to the waveguide plane by first-order diffraction. Second-order DFB structures provide a simple way to fabricate surface-emitting lasers. As compared to vertical geometries [V(E)CSELs], DFB lasers enable long interaction lengths of the resonant light with the gain material and thus low lasing thresholds. At the same time they show good singlemode behavior and side-mode suppression ratios and are well suited for communication and sensing applications.

For DFB lasers based on organic gain materials, various fabrication techniques for the realization of periodic surface corrugations in dielectric or polymeric substrates exist. Among these techniques, UV-light assisted nanoimprint is a simple and reliable fabrication method for robust grating substrates.

In this technique, a master grating is pressed into a crosslinkable material (e.g., ORMOCOMP), which is then photopolymerized using UV light. The master grating itself can be made of a soft material, e.g., polydimethylsiloxane (PDMS), or a hard material, like silicon dioxide (SiO2). It can also be reused for imprinting many times. Thin films of the active material with a thickness measuring a few hundred nanometers are deposited on top of the substrates to finalize the DFB laser device stack. All processes may be scaled to lateral dimensions up to several centimeters.

To take advantage of the broad emission spectrum of organic laser materials, which can extend to more than 100 nm, the resonant wavelength given by the Bragg condition has to be changed. A continuously tunable, optically pumped organic DFB laser with a tuning range of more than 50 nm around 630 nm has been realized by our group by introducing a smooth wedge-shape thickness variation of the gain layer, which consists of the organic semiconductor tris(8-hydroxyquinoline) aluminum (Alq3) that was doped with the laser dye 4-(dicyanomethylene)-2-methyl-6-(4-dimethylaminostyryl)-4H-pyran (DCM).6 As a consequence of the local thickness variation, the effective refractive index is accordingly dependent on the spatial position of the pump spot. This enables a simple tuning scheme where the laser device is mechanically shifted for wavelength control (see Fig. 1).

One major obstacle for organic lasers for real-world applications is the limited lifetime of the devices when exposed to air. Organic materials tend to degrade rapidly, which is mostly related to photo-oxidation processes that eventually quench the emission. Part of this can be circumvented by using a pulsed optical excitation. Repetition rates of the lasers are usually between 10 Hz and 10 kHz even though lasers in the megahertz regime have also been reported. Yet this implies that organic lasers cannot easily be operated in continuous-wave mode. Furthermore, the devices have to be encapsulated or operated in an inert, oxygen-free atmosphere. This can be achieved by various means and allows laser operation over as many as 107 pulses at a single pump spot. Additionally, it can be expected that efforts in the development of commercially available OLED materials will also lead to novel gain media with even higher emission efficiency and superior stability.

Spectroscopy and fluorescence applications

A laser light source for spectroscopic application was constructed by combining a compact, frequency-tripled Nd:YAG laser as pump source, the encapsulated tunable organic DFB laser, and a few other optical components. The organic laser device was mounted on a motorized translation stage that allowed the excitation of different positions on the sample. This compact system was calibrated and used for transmission spectroscopy.

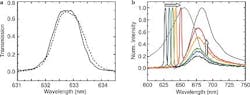

To test the system, the transmission spectrum of a narrow laser line filter with a full width at half maximum of 1 ± 0.2 nm was measured and compared to the results obtained from a commercial spectrophotometer and the same filter. The results show a good agreement of both measurements (see Fig. 2a). A further benchmark is the sensitivity determined by the highest optical density (OD) of a sample that still allows spectral characterization. Using neutral density filters, optical densities up to values of OD 5 with an accuracy greater than 96% were detected.7 Even higher sensitivities are expected with improved signal-processing techniques.

In confocal microscopy and other life science applications, the use of fluorophores is one important optical readout method for tracking and analyzing biological molecules. These fluorescent markers are usually excited with discrete laser lines from solid-state or semiconductor lasers, which only suboptimally match the absorption maximum of the marker molecule in use. This in turn can lead to unfavorable signal-to-noise ratios for fluorescence detection.

Tunable lasers can help to resolve this issue as their emission wavelength can easily be adjusted to the absorption maximum to improve fluorescence signals generated by laser excitation. This was shown in a basic experiment with the compact organic laser system and commercially available fluorescent microspheres. A clear increase of the fluorescent signal can be observed when the excitation wavelength matches the absorption maximum of the marker (see Fig. 2b)

System integration

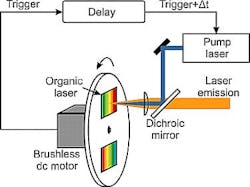

A much faster tuning scheme than the simple mechanical linear translation can be realized by mounting the DFB laser on a spinning disc. The device is excited using time-synchronized pump-laser light pulses. This tuning method enables high-speed tuning with access times below 10 ms independently of the tuning gradient (see Fig. 3).7

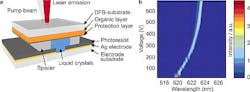

While mechanical tuning is robust and elegant, more integrated photonic microsystems require a direct electric tuning of the laser wavelength. Recently, nematic liquid crystals were placed on top of a DFB laser. With laterally aligned electrodes the refractive index of the waveguide mode can be tuned by applying an electrical field that reorients the liquid crystal molecules.

The simple device structure was fabricated from two basic device parts, the organic DFB laser and the electrodes part, which were then combined and infiltrated with the liquid crystals. With this, the DFB lasing wavelength was tuned over several nanometers by changing the applied voltage (see Fig. 4).8 The fabrication process was developed such that it can be easily adapted for integrated DFB laser sources as a part of sensing platforms.

These applications for optical transmission spectroscopy and laser-induced fluorescence show that organic semiconductor lasers have reached a degree of maturity that allows commercialization. Thus, the recently founded startup Visolas has developed a complete standalone organic laser system for this purpose.

The computer controlled system fits into an industry-standard 19-in. rack case and has a power consumption of less than 20 W. The system is designed such that the organic DFB laser chips can be used within the setup in a cartridge-like manner. One such laser chip is estimated to hold for as many as 105 full spectroscopic measurements. Using only few chips with different emission properties enables the coverage of the whole visible spectrum without the need to handle toxic solvents like in the case of solution-based dye lasers.

REFERENCES

1. T. Riedl et al., Appl. Phys. Lett., 88, 241116 (2006)

2. C. Karnutsch et al., IEEE PTL, 19, 741 (2007)

3. A. Vasdekis et al., Opt. Exp., 14, 9211 (2006)

4. H. Sakata et al., Appl. Phys. B, 92, 243 (2008)

5. Y. Yang et al., Appl. Phys. Lett., 92, 163306 (2008)

6. S. Klinkhammer et al., Appl. Phys. B, 97, 787 (2009)

7. T. Woggon et al., Appl. Phys. B, 99, 47 (2010)

8. S. Klinkhammer et al., Appl. Phys. Lett., 99, 023307 (2011)

Sönke Klinkhammer, Thomas Woggon, and Uli Lemmer are with the Light Technology Institute, Karlsruhe Institute of Technology, Karlsruhe, Germany; and Visolas, Eggenstein-Leopoldshafen, Germany; e-mail: [email protected]; www.lti.kit.edu.