European project tackles low-cost tandem organic solar cell development

Leuven, Belgium--Imec and its 16 project partners have launched the European FP7 project X10D, which aims at developing tandem organic solar cells with an increased conversion efficiency and lifetime as well as a decreased production cost. The ultimate goal of the X10D project is to bring organic photovoltaic (OPV) technologies towards introduction into the competitive thin-film PV market.

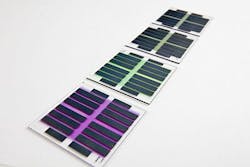

Organic solar cells hold the promise of low-cost production and high throughput, both essential parameters for the uptake of a new technology by the PV industry. However, current OPV technologies are unstable when exposed to the ambient environment, and their power conversion efficiencies are not sufficient to be viable alternatives to the current dominating silicon photovoltaic technologies. By applying new designs and architectures, materials and manufacturing technologies, the X10D project aims at increasing the power conversion efficiency to achieve at least a 12% on cell level (1cm²), and 9% on module level (100 cm²). Moreover, the X10D project has set its goal to guarantee a minimum of 20 years lifetime for OPV modules on glass and 10 years on foil, and to decrease the cost below 0.70 €/watt peak.

X10D gathers the available OPV knowledge and expertise from universities, research institutes, and companies in Europe. Furthermore, X10D brings together a complete and unique OPV research and development consortium covering both solution-processed as well as small molecule-based OPV expertise. Each segment of the value chain is represented in the project: materials development and upscaling; device development and upscaling; large-area deposition equipment and processes; novel transparent conductors; laser scribing equipment and processes; encapsulation technologies; energy, life cycle, and cost analysis; and end users.

-----

Follow us on Twitter

Subscribe now to Laser Focus World magazine; it's free!