Aligned carbon nanotubes form robust, efficient terahertz polarizer

Houston, TX--Researchers at Rice University—a place from which much carbon-nanotube research originates these days—have created an extremely efficient and robust terahertz-radiation polarizer from carbon nanotubes.1 The broadband polarizer handles radiation from 0.5 to 2.2 THz, far surpassing the range of commercial polarizers that consist of fragile grids wrapped in gold or tungsten wires.

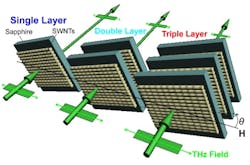

The device consists of a triple layer of carbon nanotube arrays on sapphire bases. It either allows 100% of terahertz radiation to pass through or blocks 99.9% of it, depending on the polarization. It could be integrated into terahertz optical systems for new security and communication devices, sensors, and noninvasive medical-imaging systems.

"We have pretty good terahertz emitters and detectors, but we need a way to manipulate light in this range," says Junichiro Kono, one of the researchers. He notes that impressive progress has been made particularly in terahertz quantum-cascade lasers.

Two of the paper's co-authors, Rice University professor Robert Hauge and his former graduate student Cary Pint, developed a way to grow nanotube carpets and to transfer well-aligned arrays of nanotubes from a catalyst to any substrate they chose, limited only by the size of the growth platform. At about the same time, Kono's lab began working with carbon nanotube arrays transferred onto a sapphire substrate by Pint and Hauge. Those aligned arrays turned out to be very effective at polarizing terahertz radiation, as Kono and his team reported in a 2009 paper.

Electrical manipulation in the future

Kono sees use for the device beyond terahertz spectroscopy by manipulating it with an electric field, but that will only become possible when all of the nanotubes in an array are of a semiconducting type. As they're made now, batches of nanotubes are a random mix of semiconductors and metallics; recent work by Erik Hároz, a graduate student in Kono's lab, detailed the reasons that nanotubes separated through ultracentrifugation have type-dependent colors. But finding a way to grow specific types of nanotubes is the focus of a great deal of research at Rice and elsewhere.

The paper was coauthored with researchers at the Institute of Laser Engineering at Osaka University, Japan. The Department of Energy, the National Science Foundation, and the Robert A. Welch Foundation supported the research.

REFERENCE:

1. Lei Ren et al., Nano Letters, Article ASAP; DOI: 10.1021/nl203783q; Publication Date (Web): January 23, 2012.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.