Graphene quantum dots are fabricated in bulk from ordinary carbon fiber

Houston, TX--An international team of researchers has learned how to simply transform conventional carbon fiber into graphene quantum dots (QDs).1 Carbon is cheap and common; QDs are increasingly useful in photonics and biophotonics.

The team has members at Rice University, as well as in China, India, Japan and the Texas Medical Center. They have developed a one-step chemical process that is markedly simpler than established techniques for making graphene QDs.

"There have been several attempts to make graphene-based quantum dots with specific electronic and luminescent properties using chemical breakdown or e-beam lithography of graphene layers," says Pulickel Ajayan, one of the Rice University researchers. "We thought that as these nanodomains of graphitized carbons already exist in carbon fibers, which are cheap and plenty, why not use them as the precursor?"

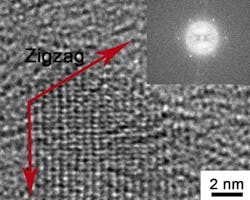

The sub-5-nm carbon-based QDs produced in bulk through the wet chemical process discovered at Rice are highly soluble, and their size can be controlled via the temperature at which they're created.

The Rice researchers were attempting another experiment when they came across the technique. "We tried to selectively oxidize carbon fiber, and we found that was really hard," says Wei Gao, a Rice graduate student who worked on the project with lead author Juan Peng, a visiting student from Nanjing University who studied in Ajayan's lab last year. "We ended up with a solution and decided to look at a few drops with a transmission electron microscope."

The specks they saw were oxidized nanodomains of graphene extracted via chemical treatment of carbon fiber. "That was a complete surprise," Gao says. "We call them quantum dots, but they're two-dimensional, so what we really have here are graphene quantum discs."

Further experimentation revealed that the size of the QDs, and thus their photoluminescent properties, could be controlled through processing at relatively low temperatures, from 80 to 120 degrees Celsius. "At 120, 100 and 80 degrees, we got blue, green, and yellow luminescing dots," Gao says.

Their luminescent properties give graphene QDs potential for imaging, protein analysis, cell tracking, and other biomedical applications, Gao says. Tests at Houston's MD Anderson Cancer Center and Baylor College of Medicine on two human breast cancer lines showed the QDs easily found their way into the cells' cytoplasm and did not interfere with their proliferation.

"The green quantum dots yielded a very good image," says co-author Rebeca Romero Aburto, a Rice graduate student in the Ajayan lab. "The advantage of graphene dots over fluorophores is that their fluorescence is more stable and they don't photobleach. They don't lose their fluorescence as easily. They have a depth limit, so they may be good for in vitro and in vivo (small animal) studies, but perhaps not optimal for deep tissues in humans. But everything has to start in the lab, and these could be an interesting approach to further explore for bioimaging. In the future, these graphene quantum dots could have high impact because they can be conjugated with other entities for sensing applications, too."

REFERENCE:

1. Juan Peng et al., Nano Letters, publication date (Web): January 4, 2012; DOI: 10.1021/nl2038979

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.