Glass-based inorganic UV LED aims for biomedical use

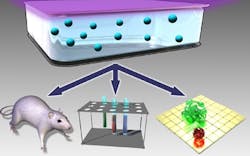

Los Alamos, NM--A multinational team of scientists has developed a process for creating glass-based inorganic UV-emitting LEDs based on tin dioxide (SnO2) nanoparticles embedded in silicon dioxide (SiO2) thin films.1 Fabricated using solution processing, the 390-nm-emitting LEDS have a maximum external quantum efficiency of about 0.3%. The work is a step toward biomedical devices with nanostructured LEDs on silicon chips integrated into, for example, a "lab on a chip."

The team includes scientists from the University of Milano-Bicocca (Italy), Los Alamos National Laboratory (LANL; Los Alamos, NM), and the Massachusetts Institute of Technology (Cambridge, MA).

Needed for biomedical use

LEDs based on solution-processed inorganic nanocrystals have promise for use in environmental and biomedical diagnostics, because they are cheap to produce, robust, and chemically stable. But development has been hampered by the difficulty of achieving UV emission. But the team's fabrication process overcomes this problem and opens the way for integration in a variety of applications.

The world needs light-emitting devices that can be applied in biomedical diagnostics and medicine, either as active lab-on-chip diagnostic platforms or as light sources that can be implanted into the body to trigger some photochemical reactions, says Sergio Brovelli of LANL. Such devices could, for example, selectively activate light-sensitive drugs or probe for the presence of fluorescent markers in medical diagnostics. These devices would need to be fabricated cheaply on a large scale and integrated into existing technology.

The new UV LEDs are inorganic and combine the chemical inertness and mechanical stability of glass with the property of electric conductivity and electroluminescence. As a result, they can be used in harsh environments, such as immersion into physiologic solutions, or by implantation directly into the body. This was made possible by designing a new synthesis strategy that allows fabrication of all-inorganic LEDs via a wet-chemistry approach (a series of simple chemical reactions in a beaker). Importantly, this approach is scalable to industrial quantities with a very low start-up cost.

REFERENCE:

1. Sergio Brovelli et al., Nature Communications (2012); doi: 10.1038/ncomms1683.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.