Integrated GRIN lens could couple light efficiently into silicon photonic circuits

Singapore--Qian Wang and his group at the Agency for Science, Technology, and Research (A*STAR) Data Storage Institute have developed a graded-refractive-index (GRIN) lens that can be directly integrated on a silicon chip at the end of an optical waveguide, serving as a highly efficient coupler between the waveguide and a standard single-mode fiber (SMF).1 These couplers, which along with an antireflection coating show a coupling efficiency of 90% between a 300-nm-thick silicon waveguide and a standard SMF, can be key to getting signals on and off a silicon-photonics chip with a large alignment tolerance.

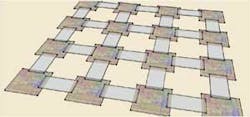

Alternating layers of two materials

Silicon is a promising platform for dense photonic integration. Because the technology required for processing silicon to create such photonic circuits already exists, the use of silicon waveguides is attracting attention from the electronics industry. The challenge, however, is to be able to insert and extract a beam of light efficiently into and out of such small structures. GRIN lenses are one approach, as long as they can be integrated into the silicon manufacturing process.

"We now propose a computational algorithm that can generate a novel graded-refractive-index profile for the GRIN lens and thus achieve aberration-free subwavelength focusing and highly efficient coupling," says Wang.

The GRIN structure consists of a stack of alternating layers of two materials—for example silicon, which has a high refractive index, and silicon dioxide, which has a low refractive index. The layers of silicon are thicker than those of silicon dioxide at the optical axis, but this gradually reverses higher up in the stack.

So far, the concept exists only in the realm of simulation; the next step will be to demonstrate this concept experimentally. "We plan to incorporate the idea into an electronic-photonic integration platform," says Wang.

REFERENCE:

1. Qian Wang et al., IEEE Journal of Selected Topics in Quantum Electronics, Vol. 17, No. 3, p. 581 (2011).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.