Solution-produced calcium carbonate microlens arrays are biocompatible

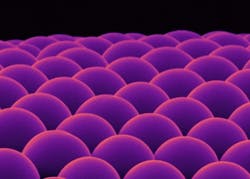

Potsdam, Germany--Calcium carbonate (CaCO3) microlens arrays can be fabricated quickly and without the need of a cleanroom environment, say researchers at the Max Planck Institute of Potsdam, the University of Konstanz, and KAIST (Daejeon, Korea). In the technique, CaCO3 structures form within a few minutes on a solution saturated with calcium; the structures grow into a thin film within one or two hours. With the addition of an organic surfactant, they then form uniform hemispheres in regular arrays. This simplicity is in contrast with conventional photolithographic and other techniques for making microlens arrays.

The researchers could observe clear multiple images of a micron-sized 'A' projected through the array of microlenses. “The high quality of the microlenses was a huge surprise to us,” says Wolfgang Wagermaier, a materials scientist at the Max Planck Institute in Potsdam. “This was the first time anyone had ever demonstrated such optical properties in synthetically produced CaCO3 structures.” The lenses have a diameter of 0.006 mm and a focal length of 0.007 to 0.008 mm.

The researchers took their cue from the natural world: the marine brittlestar Ophiocoma Wendtii is covered with crystalline microlenses of CaCO3, which together form a type of compound eye. The brittlestar's crystalline lenses are aligned so that the birefringence that is typical of CaCO3 does not affect them, meaning that no double image is produced. The lenses are also shaped to correct for spherical aberration.

The researchers were able to demonstrate that their lab-made microlenses are compatible with biological substances; as a result, the lenses could potentially be used in fields such as cell research.

“Deriving fundamental principles for material synthesis from the way in which natural materials are formed is usually an enormous challenge," says Peter Fratzl, who heads the Department of Biomaterials at the Max Planck Institute of Colloids and Interfaces. "Sometimes we also get pleasant surprises, like this discovery of a relatively easy method of producing optical elements modeled on nature."

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.