Laser-fused dentures now half the cost of milled versions

Lichtenfels, Germany--Laser cusing (also known as laser-fusing, laser sintering, or laser additive manufacturing or LAM processes) Mlab systems from Concept Laser are being used by Laufer Zahntechnik GmbH (Mannheim, Germany) to create dentures at half the cost of milled versions.

Most dental restorations use conventional techniques such as mould-based casting or milling from the complete workpiece, with milling currently being the most widely used technique. These manufacturing methods have weaknesses in terms of quality, take time, and cost approximately $26 for a milled unit. But with laser fusing, Laufer Zahntechnik says they can offer the same denture unit for $13--half the cost.

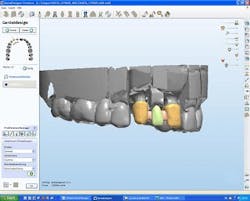

Today Laufer works with LaserCUSING (trade-marked) machines of the Mlab cusing type made by Concept Laser. Further technical progress has been made thanks to CAMbridge software, which allows automatic support generation and automatic positioning of the crowns and bridges on the build plate. With fully automatic generative fabrication, on average 80 units are fabricated simultaneously on one build plate per day. The enormous cost advantages of this method lie in the batch size. The labor costs can also be reduced significantly: Instead of employing 6 to 7 dental technicians for completely conventional cast fabrication, only 4 employees are now required to produce the same quantity of product using the generative metal laser melting process.

But the fully automatic fabrication overnight not only speeds up the technical production time itself, but also offers an enormous saving in terms of time for dentists as service partners: They can take an impression of the patient in the morning and send it to the laboratory. At Laufer the associated plaster-cast model is then created and scanned in, and the denture is designed. Towards the end of the working day, the build job which is prepared with CAMbridge is started on the Mlab cusing machine. Fabrication then takes place fully automatically overnight. The next morning the denture parts are subjected to a heat treatment at Laufer and then detached from the build plate. After certain finishing and veneer processes, dentists can insert the dentures into the mouths of their patients in the space of two days.

Laufer's range of customers now includes around 500 dental practices.

SOURCE: Concept Laser; www.concept-laser.de