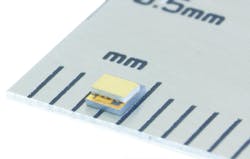

Thin-film TEC available from Nextreme Thermal Solutions

The eTEC HV14 thin-film thermoelectric cooling module measures 3 mm2 and 0.6 mm high, and can pump up to a maximum power density of 120 W/cm2 compared to <10 W/cm2 for the bulk TEC. The response time is on the order of milliseconds. It provides 55°C of cooling performance at an ambient temperature of 25°C.Nextreme Thermal Solutions

Durham, NCwww.nextreme.com

-----

PRESS RELEASE

NEXTREME ACHIEVES 55°C COOLING PERFORMANCE IN PRODUCTION-LEVEL THIN-FILM THERMOELECTRIC COOLERS

Thin-film thermoelectric devices provide new levels of thermal management performance...

DURHAM, N.C. (April 25, 2012) - Nextreme Thermal Solutions, the leader in micro-scale thermal management and power generation solutions, today announces the availability of new thin-film thermoelectric cooling products that offer 55°C of cooling performance at an ambient temperature of 25°C. The 55°C temperature milestone, known as the Tmax, reflects the ability of the thermoelectric device to pump heat efficiently. This new level of performance translates to improved cooling efficiency, lower input power requirements, and greater opportunities for solving thermal issues in electronics, photonics and avionic applications. Nextreme will be introducing new products with this higher level of cooling performance in late second quarter 2012.

The electronic industry's continued trend of smaller form factors, greater circuit density, and highly integrated packaging has translated into significant thermal problems for optoelectronics manufacturers. Bulk TEC devices have been used to provide temperature control of laser diodes and other optoelectronic devices, but have not kept pace with these new requirements due to their larger size and power density limitations. With Nextreme's thin-film modules, manufacturers of laser diodes, photodiodes, infrared (IR) sensors and other semiconductor chips can now integrate cooling and temperature control functionality directly into the package during assembly, resulting in a high-volume, lower cost thermal management solution.

The Nextreme eTEC HV14 is one of the world's smallest thermoelectric modules with a footprint of only 3 mm². The thin-film module can pump up to a maximum power density (Qmax/area) of 120 W/cm² in comparison to less than 10 W/cm² for the bulk TEC. The response time of the eTEC HV14 is on the order of milliseconds compared to seconds for bulk devices. These devices are only 0.6mm high, making them the thinnest, highest heat pumping thermoelectric coolers on the market today.

The miniature size and heat pumping capability make thin-film thermoelectric modules ideal for cooling laser diodes, photodiodes, LEDs, infrared (IR) sensors, pump lasers, crystal oscillators and optical transceivers.

The eTEC thin-film thermoelectric cooling product line will be available through Laird Technologies, Inc., Nextreme's world-wide strategic distribution and design partner, and through Mouser.com.

More information on Nextreme's thermoelectric technology can be found at www.nextreme.com. Contact Nextreme at 3908 Patriot Drive, Suite 140, Durham, NC 27703-8031; call (919)-597-7300; e-mail [email protected]; or go to www.nextreme.com.

About Nextreme Thermal Solutions, Inc.

Nextreme Thermal Solutions is a leading manufacturer of thin-film thermoelectric modules and sub-systems for growing markets worldwide. Micro-scale form factors, high power-pumping capabilities and a high-volume semiconductor manufacturing process enable low-cost, high-performance thermal management and energy harvesting solutions. For more information, visit www.nextreme.com.

-----

Subscribe now to Laser Focus World magazine; it's free!