Micro-optical device has optomechanical nonlinear light switch

Minneapolis/St. Paul--A team of scientists and engineers at the University of Minnesota has invented a microscale optical device that uses the force generated by light to flip a mechanical switch of light on and off at a very high speed.1 This development could lead to advances in computation and signal processing using integrated photonics instead of electronics, resulting in higher performance and lower power consumption.

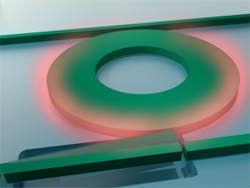

The new device has two optical waveguides, each carrying an optical signal. Placed between the waveguides is an optical resonator in the shape of a microscale donut. Light can circulate hundreds of times in the resonator, gaining intensity through resonance.

Strong signal relayed by weaker signal

Using this effect, the optical signal in the first waveguide is significantly enhanced in the resonator and generates a very strong optical force on the second waveguide. The second waveguide is released from the supporting material so that it moves in oscillation, like a tuning fork, when the force is applied on it. This mechanical motion of the waveguide alters the transmission of the optical signal. Because the power of the second optical signal can be many times higher than the control signal, the device functions like a mechanical relay to amplify the input signal.

Currently, the new optical-relay device operates at 1 MHz. Researchers expect to boost this to several gigahertz. The mechanical motion of the current device is sufficiently fast to connect radio-frequency devices directly with fiber optics for broadband communication.

“This device is similar to electromechanical relays but operates completely with light,” says Mo Li, an assistant professor of electrical and computer engineering in the University of Minnesota’s College of Science and Engineering.

The new study is based on a previous discovery by Li and collaborators in 2008 where they found that nanoscale light conduits can be used to generate a strong enough optical force with light to mechanically move the optical waveguide. In the new device, the researchers found that this force of light is so strong that the mechanical property of the device can be dominated completely by the optical effect rather than by its own mechanical structure. The effect is amplified to a point where it controls light signals at additional wavelengths that are at a much higher power level.

“This is the first time that this novel optomechanical effect is used to amplify optical signals without converting them into electrical ones,” says Li.

REFERENCE:

1. Huan Li et al., Nature Communications, Vol. 3, No 1091 (2012); doi:10.1038/ncomms2103

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.