Ultrathin optical fiber from FBGS improves sensing in composites and textiles

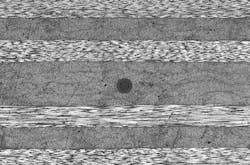

Jena, Germany and Geel, Belgium--FBGS has launched ultrathin (80 micron diameter) optical fibers for improved sensing in composites and smart textiles. Because the ability to embed fiber Bragg grating (FBG)-based sensors within a material gives engineers the ability to measure intrinsic strain of components during their production, or use under varying load conditions, one of the most demanding attributes of the optical sensing fiber is small size. These new FGBS DTG (draw tower grating) fibers offer several improvements over standard 125 micron diameter DTG fibers.

Thinner fibers are (1) less invasive when embedded within laminate composite structures or textiles; (2) require less force to be strained, making them more suitable for acoustic sensors and hydrophones; and (3) the thinner fibers are more "elastic" in respect to bending properties for improved use in applications where small bend radii are required.

The 80 micron diameter DTG fiber has been released as a Beta-product for the 1550 nm window and is drawn with an Ormocer coating that brings the outer fiber diameter to about 114 microns. It retains all the attributes of the larger 125 µm DTG product, including extremely high mechanical strength, spliceless FBG chains as the Bragg gratings can be embedded at any position along very long or customer-specific lengths of fiber, low bending loss (high NA fiber), wide temperature range of operation (cryogenic to +200 degrees C), Ormocer coating, and uniform coating even at the FBG position.

CEO Hugo Mertens says, "This development has come mainly as a result of market forces. The composite and textile industry is very exciting and manufacturers in this sector are starting to incorporate DTG's for sensing applications. We are simply responding to requests for a fiber that is less invasive to the host material and at 80µm it is all but invisible."

FBGS would like to build collaborations with those companies that share this vision for "smart materials" and invites you to contact them at [email protected].

SOURCE: FBGS; www.fbgs.com

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.