Coating that mimics firefly scales makes LEDs more efficient

Namur, Belgium--Jagged microscopic scales covering the surface of a firefly's light-emitting abdomen make an excellent light-extraction layer for LEDs, as researchers from Belgium, France, and Canada discovered. They then created an LED overlayer that increased light extraction by up to 55%.1, 2 The researchers hail from the University of Namur (Namur, Belgium); European Synchrotron Research Facility (Grenoble, France); Université Catholique de Louvain (Louvain-la-Neuve, Belgium); and Université de Sherbrooke (Québec, Canada).

The researchers determined that it was misfit of the small, transparent scales that produced roughness and thus a microscale (pun intended) reflection-reducing coating.

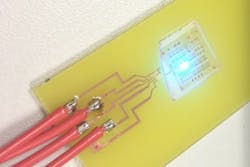

The LED overlayer inspired by the firefly scales was arrived at by modeling the firefly scales, then optimized for the high-refractive-index semiconductor material of a gallium nitride (GaN) based LED (on which it was then applied). No redesign of the diode geometry was needed.

“The most important aspect of this work is that it shows how much we can learn by carefully observing nature,” says Annick Bay, a Ph.D. student at the University of Namur in Belgium who studies natural photonic structures, including beetle scales and butterfly wings. When her advisor, Jean Pol Vigneron, visited Central America to conduct field work on the Panamanian tortoise beetle (Charidotella egregia), he also noticed clouds of fireflies and brought some specimens back to the lab to examine in more detail.

Micro (not nano)-scale

Using scanning electron microscopes, the researchers identified structures such as nanoscale ribs and larger, misfit scales on the fireflies’ cuticles. When the researchers used computer simulations to model how the structures affected light transmission they found that the sharp edges of the jagged, misfit scales let out the most light. The finding was confirmed experimentally when the researchers observed the edges glowing the brightest when the cuticle was illuminated from below.

“We refer to the edge structures as having a factory roof shape,” says Bay. “The tips of the scales protrude and have a tilted slope, like a factory roof.” The protrusions repeat approximately every 10 microns, with a height of approximately 3 microns. “In the beginning we thought smaller nanoscale structures would be most important, but surprisingly in the end we found the structure that was the most effective in improving light extraction was this big-scale structure,” says Bay.

Nicolas André, a postdoctoral researcher at the University of Sherbrooke in Canada, deposited a layer of light-sensitive material on top of the GaN LEDs and then exposed sections with a laser to create the triangular factory-roof profile. The higher index of the LEDs required a height and width of 5 microns to maximize the light extraction.

The Belgium-led team is the first to identify micrometer-scale photonic features, which are larger than the wavelength of visible light, but which surprisingly improved light extraction better than the smaller nanoscale features.

REFERENCES:

1. “Improved light extraction in the bioluminescent lantern of a Photuris firefly (Lampyridae),” Optics Express, Vol. 21, Issue 1, pp. 764-780 (2013).

2. “An optimal light-extracting overlayer, inspired by the lantern of a Photuris firefly, to improve the external efficiency of existing light-emitting diode,” Optics Express, Vol. 21 Issue S1, pp. A179-A189 (2013).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.