OCT can improve plastic gradient-index lens manufacture

Rochester, NY--Researchers at the University of Rochester are using optical coherence tomography (OCT) to get high-resolution 3D images of the internal structure of a new form of gradient-index (GRIN) lens. Called the S-GRIN, the new lens has a spherical refractive-index gradient; the breakthrough in the lens is that it is manufacturable, leading to potential uses for lightweight single-lens cameras, night-vision goggles, and ball lenses for solar collectors.

Using OCT during lens manufacture allows the researchers to significantly improve the quality of the S-GRIN lenses. The results are published this week in Scientific Reports, a Nature Publishing Group journal.

Many animals have eyes that are effectively S-GRINs, which gives them more focusing power, sharper images and a lower number of components. For example, human eyes have a refractive-index gradient of about 0.03. The S-GRIN lenses have a gradient of more than 0.08, which is unusually high, and can help with chromatic aberrations.

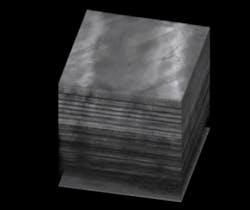

S-GRINs consist of thousands of layers of compressed plastic bent into a lens-type shape. By using OCT, Jannick Rolland, Brian J. Thompson Professor of Optical Engineering at Rochester's Institute of Optics, and her team were able to look at each of these layers individually. They could see all the features of the material down to micron-scale, obtaining high-resolution 3D images, giving a more precise characterization of the lens' refractive-index distribution.

Rolland and her team are collaborating with Michael Ponting from PolymerPlus (Valley View, OH), who is developing the manufacturing process for this cutting-edge technology lens, which was invented by Professor Eric Baer at Case Western Reserve University (Columbus, OH). By being able to show the whole lens structure, Rolland and her team were able to pinpoint some areas of the manufacturing process that could be improved. For example, they saw that some of the layers were thicker than the company had hoped for. The feedback offered by OCT allowed S-GRINs to be improved significantly.

S-GRINs are made from plastic, which offers many advantages to glass for lenses: it is lighter and more easily deformed into different shapes. Plastic optics have their own challenges however, consistency and high-quality among them. Rolland believes that embedding OCT in the manufacturing process can begin to address these challenges.

This work was supported by the Manufacturable Gradient Index Optics program of DARPA and by the NYSTAR Foundation.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.