Boston, MA--The distributed fiber-optic sensor (http://www.laserfocusworld.com/articles/2013/01/fiber-optic-sensing-distributed-fiber-optic-sensing-solves-real-world-problems.html) market is forecast to be $586 million in 2013 and projected to be $1.1 billion in 2016 with 70% associated with the oil and gas segments, according to a recent market survey report conducted by the Photonic Sensor Consortium and published by Information Gatekeepers (IGI Group). "When the positive and negative factors are considered, all of the fiber-optic sensor companies that were surveyed are optimistic about future growth with 100% of the companies surveyed forecasting market expansion at 10% or higher," says David Krohn, author of the Photonic Sensor Consortium Market Survey Report. Krohn is Chairman of the Photonic Sensor Consortium and managing partner of Light Wave Venture LLC.

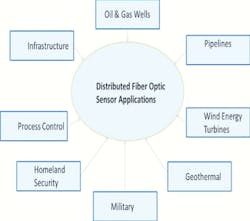

Fiber-optic distributed sensors represent a technology base that can be applied to a multitude of sensing applications with several characteristic advantages of fiber optics that make their use especially attractive for sensors. The forecast covers distributed fiber-optic sensing systems including sensor elements, fiber-optic cables, interrogators and software. The worldwide markets covered (excluding China) include oil & gas (seismic, in-well, pipelines) (http://www.laserfocusworld.com/articles/print/volume-47/issue-4/features/photonics-applied-optical-sensing-downhole-sensing-puts-fiber-optics-to-the-test.html), wind energy turbines (http://www.laserfocusworld.com/articles/print/volume-48/issue-05/features/wind-energy-gets-a-boost-from-wind-turbine-lidar.html), geothermal wells, utility power lines, military (hydrophone, security, shipboard), homeland security (intrusion and chemical monitoring), infrastructure monitoring, and industrial process control.

Most physical properties can be sensed optically with fibers. Light intensity, displacement (position), temperature, pressure, rotation, sound, strain, magnetic field, electric field, radiation, flow, liquid level, chemical analysis, and vibration are just some of the phenomena that can be sensed.

Fiber-optic sensors have been used successfully for many years in military gyroscopes and hydrophones. However, their use in smart oil wells has been the key to enabling North America to be on a path to energy independence.

The Photonics Sensor Consortium in conjunction with Light Wave Venture was started in 2003 as an independent organization to assist in the market development and commercialization of photonic sensor technology. The primary focus has been on distributed fiber-optic sensors. Over the last 10 years, the Consortium has tracked the market and provided overall projections and market analysis for active participants. This report is the first to be available to the general photonics industry.

SOURCE: IGI Group; http://www.igigroup.com

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.