Off-the-shelf, 4.2-mm-diameter MEMS mirrors are now available in any quantity with either gold or aluminum coatings. The bonded, modular mirror can be mounted on a variety of the companyâs actuators, and may be ordered in packages ranging from large 24-pin dual-in-line (DIP24) to LCCs of different sizes.

Mirrorcle Technologies

Richmond, CA

www.mirrorcletech.com

-----

PRESS RELEASE

Mirrorcle Technologies announces availability of 4.2mm diameter MEMS mirrors

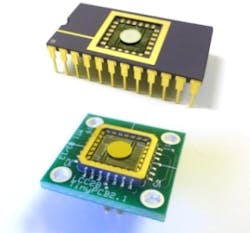

Mirrorcle Technologies, Inc (MTI), the California-based manufacturer of patented, gimbal-less MEMS micromirror devices, today announces the availability of a larger category of mirrors. Until now, the company has been offering integrated mirror devices ranging from 0.8mm to 1.7mm in diameter, and bonded mirrors from 0.8mm to 3.6mm in diameter. Mirrorcleâs bonded MEMS mirror devices are modular in design, consisting of an actuator âengineâ and a mirror of customer-selected size. With a variety of different MEMS actuators, a selection of aluminum or gold mirror coating, and a selection of mirror sizes and shapes, customers are given a wide range of choices to match their varied application requirements.

Modular MEMS design allows devices to be tailored to customersâ application requirements

Larger mirrors obtain slower characteristics than smaller ones. In addition to slower point to point responses, larger mirrors could be more susceptible to environmental shock and vibration. Because of the companyâs insistence on providing high reliability products with adequate speeds, Mirrorcle Technologies has offered mirror sizes up to 3.6mm and strongly recommended that the largest mirrors be matched with largest actuators in customersâ applications. For applications that do not require large scan-angles, stiffer actuators are available in all sizes, offering greater speeds than those that offer larger tip/tilt angles. Therefore good speed and immunity to shock and vibration can be obtained in all actuator and mirror sizes, provided proper matching of their properties. Based on customersâ demand for ever larger mirror sizes, and with continued improvements in actuator designs and performance, the companyâs regular off-the-shelf offerings now also include a 4.2mm diameter mirror. All bonded mirrors of sizes 1.6mm, 2.0mm, 2.4mm, 3.0mm, 3.6mm, and 4.2mm are now available in any quantity and with either Gold or Aluminum coating. Just like the smaller bonded varieties, this mirror can be mounted on a variety of MTI actuators, and may be ordered in a selection of different packages, ranging from large 24-pin Dual-in-Line (DIP24) to LCCs of different sizes.

Mirrorcle Technologies has a track record of successfully realizing large mirror sizes upon customer demand, up to a 9.0mm diameter device that was showcased at the MTI booth at the recent SPIE Photonics West exhibition. Those, special sizes outside of the companyâs regular offering, are suitable for use with lowest angle actuators of -1° to +1° of mechanical tip/tilt. With regular sizes of up to 4.2mm, standard mechanical tip/tilt angle range is up to -5° to +5° on both axis.

Larger MEMS mirrors to cater to broader customer base

âWe are excited to announce this new availability of 4.2mm mirrors to our customers,â commented Dr. Milanovic, CEO and Founder of Mirrorcle Technologies. âA lot of applications require relatively large mirror apertures, whether in the military, medical, industrial or consumer fields. We have been getting many inquiries about the availability of larger OTS MEMS mirrors, and are happy to now be able to better cater to such demands. We add new product categories only when we are certain that we can deliver high quality, repeatability, attractive cost, and very short lead times. At the same time, we know that many customers have read our publications about even larger mirrors [up to 9mm] that we have realized in different R&D projects. We are always excited to try new things and take on new challenges and will continue to offer such specialization and customization R&D services in the future."

About Mirrorcle Technologies, Inc.

Mirrorcle Technologies, Inc. (MTI), founded in 2005, is a California corporation that commercially provides products and services based on its proprietary optical microelectromechanical system (MEMS) technology. Since its founding, and supported by its continuous investment in R&D, MTI has offered the world's fastest point-to-point two-axis beam-steering mirrors, as well as resonating-type micromirror devices with rates up to HD video. MTI is globally the only provider of tip-tilt MEMS actuators in combination with mirrors from 0.8mm to several mm in diameter, offering customers a wide selection of specifications to optimize their paths to successful commercialization. In addition to a variety of existing designs and in-stock products, MTI also contracts to create specialty designs and fabricate custom units for its customers.

-----

Subscribe now to Laser Focus World magazine; it's free!