Day 3 (September 18) of the 2013 Stanford Photonics Research Center (SPRC) Symposium, in contrast to the highly academic content of Day 1 and Day 2, focused on industrial lasers, lasers in molecular sensing, and concluded with an afternoon workshop on Advances in Digital Photography (which I was unable to attend). Presenters were primarily from industry rather than academia, and the sessions began with an opening presentation on the "New Potential of Fiber Lasers" from IPG Photonics CEO Valentin Gapontsev just after Tom Baer's introductory "Overview of the National Photonics Initiative".

I enjoy Gapontsev presentations not particularly for the content on the slides—which is typically a basic overview of the IPG Photonics product portfolio as was this presentation, but for the small hints he gives—if you listen carefully through his accent—about future directions and new technology areas. For example, Gapontsev says that direct-diode laser solutions will never compete with fiber lasers, which have a head start in terms of reliability and low price point that direct-diode solutions still cannot beat. As one of the only 4 or 5% of the audience who was female, I chuckled when Gapontsev put up a slide showing a woman using a laser and saying, "See, now even a woman can do welding."

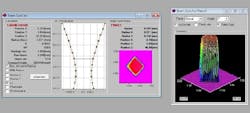

After a fire alarm forced us out of the building and we returned to hear Gapontsev's concluding slides, Magnus Bengtsson from Coherent presented "Lasers in Smart Phone Manufacturing--enabling the mobile revolution" and confirming that indeed, the laser has reached "necessary tool" status in the manufacture of smart phones; lasers are used everywhere for nearly every component in cutting, welding, marking, patterning, and yes, the drilling of silicon vias and other holes for cooling. This business of hole drilling is big with lasers; see below for a computer image showing a square hole profile that can be machined using fiber lasers from a recent Laser Focus World article on aerospace components drilling from IPG Photonics.

You can find a ton of good video on YouTube detailing the physical attributes of micromachining lasers. Here is one showing the versatility of the LPKF ProtoLaser U3 system:

For many materials, especially complex thin-film devices, Nicolas Falletto of EOlight Lasers explained in his presentation entitled "The role of pulse duration and pulse shape in laser processing of materials" that Q-switching doesn't always meet process needs and that dynamic pulse control is necessary in some applications.

And finally, presenters from Argonne National Laboratory, Picarro, and the University of Colorado, Boulder, explained the role of lasers in molecular sensing for atmospheric research, chemical detection, and even groundwater gas analysis (as an alternative to ice-core samples). The rapid pace of laser research in the sensing arena is promising, although as a regular National Geographic reader, I hope that these laser tools can help to quickly solve the many problems of atmospheric and ground-water pollution so that future generations can continue to enjoy biodiversity on the planet and participate in a future that is free to discover "what else" these magnificent lasers can do.

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.