Terahertz quantum-cascade laser emits 3 mW continuous-wave

Lausanne and Zürich, Switzerland--Researchers from Ecole Polytechnique Fédérale de Lausanne (EPFL) and Eidgenössische Technische Hochschule Zürich (ETHZ) have created a continuous-wave (CW) terahertz-radiation-emitting quantum-cascade laser (QCL) that produces single-mode surface emission with a 3 mW output power at 3.12 THz in a collimated beam. A maximum operating temperature of 100 K was achieved.

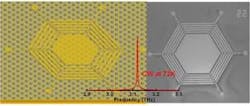

To do this, the researchers replaced the conventional loss-type boundary conditions for such a laser with a second-order Bragg grating that can diffract TM-polarized in-plane radiation at the required frequency into vertical emission. More importantly, instead of absorbing the radiation at the boundary, to ensure the single-mode operation, the Bragg grating scatters the radiation into the desired vertical emission. A high pumping efficiency with better heat flow dissipation is achieved: The new design enables CW operation that is significantly improved in terms of maximum output power and operating temperature.

Background

Since the first QCL was demonstrated in 1994 and implemented in the terahertz regime in 2002, these lasers have become one of the most important solid-state light sources in this frequency range. The use of metal-metal (MM) waveguides was a key improvement in moving QCL wavelength from the mid-IR to the terahertz range, allowing for subwavelength field confinement. Nevertheless, this type of confinement leads to a highly divergent beam from the facet.

Different strategies like photonic-crystal (PhC) or metallic-grating distributed-feedback (DFB) patterning for in-plane or vertical emission have been developed. However, most of these operate in a pulsed mode, with CW operation limited and far from being optimized.

While an absorbing boundary is commonly used to control the optical performance of a laser in MM confinement, this approach increases the total loss in the device and results in a large threshold current density, limiting the CW maximum output power and operating temperature.

The two-dimensional PhC structure created by the Swiss researchers with a second-order Bragg-grating extractor to simultaneously provide the boundary condition necessary for mode selection produces a highly collimated far-field pattern—an important step towards real-world applications in astrophysics, biology, sensing, environmental and pollutant monitoring, and security screening. Another advantage; the laser’s maximum operating temperature of 100 K is above the boiling point of liquid ntrogen (N2), allowing relatively straightforward N2 cryogenic cooling.

Source: http://phys.org/news/2013-10-continuous-wave-terahertz-lasers.html

REFERENCE:

1. Zhaolu Diao et al., Laser & Photonics Reviews, Vol. 7, Issue 5, p. L45, September 2013; doi: 10.1002/lpor.201300035

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.