UV LEDs help detect hydrocarbon contaminants in water

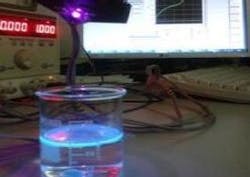

Madrid, Spain--Researchers at the Universidad Politécnica de Madrid (UPM) are developing hydrocarbon early-detection devices for rivers and other bodies of water to prevent contamination that could seriously affect the environment. The new devices use ultraviolet (UV) LEDs to detect traces of hydrocarbons in water via fluorescence.

Many contaminants are being detected in rivers and reservoirs (by measuring pH, conductivity, oxygen level, and so on); however, some contaminants, such as hydrocarbons, are only found occasionally (usually by accident). The UV-fluorescence approach is noninvasive and can both detect and identify hydrocarbons.

Other researchers who use the UV-fluorescence approach are more focused on the marine environment and also use high-output lasers as light sources. Once the samples are collected, they are carried to a lab for identification—a time-intensive procedure. The UPM LEDs, in contrast, allow for a quick, robust, and affordable measurement system.

The UPM researchers are testing to make sure the UV LEDs function consistently in bad weather conditions, varying humidity, and different temperatures. The UV LEDs produce predictable spectra that allow the identification of common hydrocarbons such as diesel oil, gasoline, and automotive lubricating oil. The concentrations of varying contaminants can be found using a computer algorithm to separate out the various spectra.

Source: http://www.upm.es/internacional/UPM/UPM_Channel/News/89e149917af34410VgnVCM10000009c7648aRCRD

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.