NIST calibrates thorium emission lines for use as exoplanet-spotting spectral reference

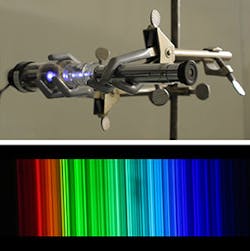

| A thorium emission lamp’s violet glow, when viewed through a spectroscope (metal tube on right in top image), is split into a spectrum of thousands of bright lines (bottom image). New measurements of these lines could help astronomers search for earthlike planets around distant stars. (Credit: Boutin/NIST) |

In the interests of astronomy, researchers at the National Institute of Standards (NIST; Boulder, CO) have more-accurately calibrated the emission spectrum of thorium -- which, because it contains thousands of lines, can serve as a reference "ruler."1

For example, one way of detecting an exoplanet orbiting another star is by monitoring light from the star system for any sign of Doppler-shifted atomic and molecular absorption lines. If a periodically varying Doppler shift is spotted, then that's a good sign an exoplanet is orbiting that star.

In fact, with the recalibrated thorium emission spectrum in hand, exoplanet-hunting data gathered over the last decade can be re-examined, possibly leading to the discovery of new exoplanets. Scientists have detected more than 400 planets using the Doppler technique, but have yet to discover a solar system similar to ours. The new data could help, says NIST physicist Gillian Nave.

"Earth causes the Sun to move at a snail's pace," says Nave. "We don't yet have techniques that can find planets of that size, but our new data will get us much closer."

The result of the thorium emission recalibration is a set of nearly 20,000 sharp spectral lines.

REFERENCE:

1. S.L. Redman et al., Astrophysical Journal, February, 2014; DOI: 10.1088/0067-0049/211/1/4