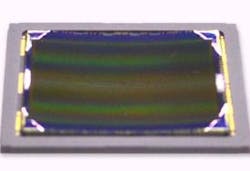

Earlier this month at the 2014 Symposia on VLSI Technology and Circuits (Honolulu, HI; June 9 to 13, 2014), Sony Corp. announced the development of spherically curved CMOS sensors; as IEEE Spectrum reports, Sony constructed its own "bending machine" for this purpose. This means that the CMOS sensors were made flat in the conventional way and then curved, rather than fabricated precurved (which would, of course require some amazing custom photolithographic equipment for patterning the CMOS).

One obvious benefit is that the curvature of the CMOS sensor can be matched to the field curvature of the imaging lens, permitting simpler lens designs with larger numerical apertures (NAs); in addition, the incidence angle of the chief ray is closer to normal, reducing reflections from the sensor.

A less-obvious (and to me more startling) feature, according to the IEEE Spectrum story, is that the strain on the silicon alters the bandgap, lowering the dark noise and making the device more sensitive (2X at the edge, 1.4X at the center).CCDs can be bent, too

As Image Sensors World noted in a blog on June 13, the German company Andanta GmbH (Olching, Germany) announced curved CCDs (cylindrical or spherical, convex or concave curvature) back in 2012.

Andanta GmbH is a company specializing in custom image sensors for astronomy, spectroscopy, and other uses, or, as the company's website states, "optimum image sensing solutions for special applications in small niches." The company even has "some standard products available, which may serve as a basis for discussion."If you go to http://www.andanta.de/en/e-unternehmen.html and download the product release entitled "New products 2012, Spherical CCD-sensors, InGaAs-Matrix Sensor FPA640x512-TE2," you'll find the curved CCDs described, with little fanfare, as:

- Custom concave or convex, various radii of curvature

- Also cylindrical (1‐dimensional spherical)

- e.g. 4k x 4k (16MPixel) spherical CCD (see figure)

Andanta uses a vacuum to pull the 4k x 4k CCD against a spherical mount. Interestingly, Andanta says, according to the Image Sensors World post, "The applied vacuum technology (also usable on back side illuminated CCDs) has not created any measurable increase in detector noise or the number of cosmetic defects compared to the conventional flat image sensor with identical electro-optical properties."

So for a bent CCD, there appears to be no reduction in dark noise as there is for a bent CMOS sensor.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.