For fabricating certain parts for spacecraft, engineers sometimes need custom parts that traditional manufacturing techniques and standard 3D printers can't create, because the parts need to have properties of multiple metals in differenent areas of the part. Now, researchers at NASA's Jet Propulsion Laboratory (JPL; Pasadena, CA) are implementing a laser-based additive manufacturing process that transitions from one metal or alloy to another in a single object.1

"You can have a continuous transition from alloy to alloy to alloy, and you can study a wide range of potential alloys," said R. Peter Dillon, a technologist at JPL. "We think it's going to change materials research in the future."

Although gradient alloys have been created in the past in research and development settings, this is the first time these composite materials have been used in making objects, such as a mount for a mirror, said John Paul Borgonia, a JPL mechanical engineer.

Why would you need to make a machine part like this? Say you want a metal object where you would like the ends to have different properties. One side could have a high melting temperature and the other a low density, or one side could be magnetic and the other not. Of course, you could separately make both halves of the object from their respective metals and then weld them together. But the weld itself may be brittle, so that your new object might fall apart under stress. That's not a good idea if you are constructing an interplanetary spacecraft, for example, which cannot be fixed once it is deployed.

JPL scientists have been developing a technique to address this problem since 2010. An effort to improve the methods of combining parts made of different materials in NASA's Mars Science Laboratory mission, which safely landed the Curiosity rover on the Red Planet in 2012, inspired a project to 3D print components with multiple alloy compositions.

Researchers from JPL, the California Institute of Technology (Caltech; Pasadena, CA), and Pennsylvania State University (University Park, PA) joined forces to tackle the issue. The result has implications for space travel and machinery on our own planet.

"We're taking a standard 3D printing process and combining the ability to change the metal powder that the part is being built with on the fly," says Douglas Hofmann, a researcher in material science and metallurgy at JPL, and visiting associate at Caltech. "You can constantly be changing the composition of the material."

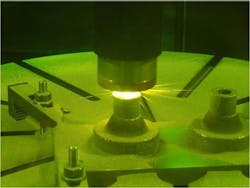

Laser-melted layers on a rotating rod

In their new technique, Hofmann and his colleagues deposit layers of metal on a rotating rod, thus transitioning metals from the inside out, rather than adding layers from bottom to top, as in the more-traditional 3D printing technique. A laser melts metal powder to create the layers.

One application already demonstrated is low-coefficient-of-thermal-expansion radially graded metal inserts for carbon-fiber spacecraft panels.

Future space missions may incorporate parts made with this technique. The auto industry and the commercial aerospace industry may also find it useful, Hofmann says.

The work was funded by NASA. Caltech manages JPL for NASA.

Source: http://www.jpl.nasa.gov/news/news.php?release=2014-247

REFERENCE:

1. Douglas C. Hofmann et al., Scientific Reports (2014); doi: 10.1038/srep05357

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.