Edmund Optics to demonstrate optics prototyping capabilities at SPIE Optics + Photonics 2014

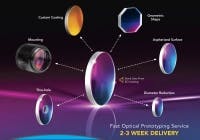

Edmund Optics' prototyping capabilities include modifications to stock components in 2–3 weeks—customizing the coating, size, shape, and edges of stock optics, improving the surface figure or accuracy of the optical surface, and sorting, mounting, kitting, and inspection, among others. Custom modifications to stock optics range from unique surface improvements, including transforming a standard PCX lens into a custom aspheric lens, to a variety of high-performance coatings on standard optics, including prisms and filters.

SPIE Optics + Photonics booth number: 125

To Learn More:

Contact:Edmund Optics

Headquarters: Barrington, NJ

Product: Optics prototyping

Key Features: Custom modifications within 2–3 weeks

What Edmund Optics says:

View more information on the company's optics prototyping.

View More Products

Locate a vendor or system integrator in our Buyer's Guide.

Share new products that you think are particularly interesting or helpful by contacting Lee Dubay, Associate Editor, Laser Focus World.