How to channel 100 kW (or more) of laser light through a single-mode fiber

Due to decades of technical refinement, today's best single-mode silica optical fiber has incredibly low optical loss; for example, Corning's commercial SMF-28 ULL fiber has an attenuation of only 0.17 dB/km at a 1550 nm wavelength. If you could see light at 1550 nm, this would mean a slab of this Corning silica 10 km thick would appear mostly transparent to you, as the slab would be transmitting more than two thirds of the light entering it.

Even at other near-IR wavelengths, such as common fiber laser wavelengths around 1 µm, solid silica does a superb job of transmitting light. For delivery of very high-power laser light, though, silica can fall short, failing or causing deleterious nonlinear effects at high-enough optical power densities.

So how can silica's performance be exceeded? One way would be through hollow-core optical fiber, which theoretically does not have the transmission limitations of solid silica. The problem is that light has a hard time staying out of the solid or structured outer fiber cladding that must be used to confine the light in a hollow fiber.

Two possible forms of hollow optical fiber are photonic bandgap fibers (PGBFs), which are familiar to readers of Laser Focus World, and hollow-core anti-resonant fibers (HC-ARFs), which use a combination of inhibited coupling to cladding modes and antiresonance to keep the light out of the cladding. So far, neither of these types has equaled the best silica fibers in transmittance.

Making nonlinear optical effects negligible

Now, Francesco Poletti of the Optoelectronics Research Centre at the University of Southampton (Southampton, England) has shown, at least theoretically, that a type of single-mode HC-ARF could do as well as or better than the best solid silica fibers in transmission, while at the same time channeling 99.995% of the light within its hollow core, resulting in very high nonlinear and damage thresholds.1

So if 100 kW of laser light were traveling through a 1 km length of this fiber, only 5 W of the light would even enter the glass cladding at all, with only a minuscule fraction of the 5 W being absorbed.

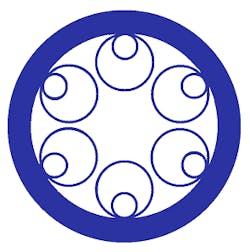

The HC-ARF fiber geometry he proposes looks like this (blue is silica glass, white is air):The difference between this and previous HC-ARF geometries is the second, smaller circle within each of the circular structures. The fiber would have a 3 dB bandwidth of about 600 nm and a 0.15 dB/km (or lower) loss at 1600 nm.

Other potential uses of this fiber include data transmission, interferometry, and mid-IR gas spectroscopy. The simplicity of the fiber geometry relative to that of PBGFs should make this fiber as easy or easier to fabricate than PBGFs.

REFERENCE:

1. Francesco Poletti, Optics Express (2014); doi: 10.1364/OE.22.023807

Note: for more info, see my update: Hollow-core antiresonant optical fibers: Part II

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.