Osram launches LED-based fitness-monitoring sensor

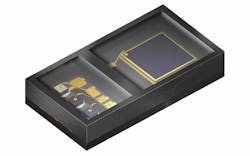

Osram Opto Semiconductors (Regensburg, Germany) has launched the SFH 7050—its first integrated optical sensor for automatic fitness tracking. The sensor can be used in mobile devices such as smart watches and fitness armbands, and simplifies personal heart rate or pulse rate measurements during jogging, for example. The sensor contains three light-emitting diodes (LEDs) with different wavelengths. The company says the efficient design saves power and also offers high signal quality for reliable measurements. A built-in photodetector receives the reflected optical signals and is separated from the emitters by an opaque barrier.

RELATED ARTICLE: Pulse oximetry helmet protects workers against carbon monoxide poisoning

The three emitters built into the sensor have wavelengths of 530 nm (green), 660 nm (red), and 940 nm (infrared). These enable the pulse at the wrist or fingertip and the oxygen content of the blood at the fingertip to be measured. The emitters can be controlled individually so the sensor can be used for different applications. Green light has become established as the best option for measuring the pulse at the wrist. Red or infrared emitters are generally used for measuring the pulse at the finger as they can then also measure the oxygen content of the blood (pulse oximetry).

Each of the three emitters is based on efficient thin-film chip technology with narrow spectral bandwidths of around 30 nm. The red LED has a specified wavelength tolerance of only ± 3 nm. "As far as measuring the oxygen content of blood is concerned, the absorption of light by blood depends largely on the wavelength of the light. The small tolerances of the red LED mean that precise measurements can be achieved with the new sensor," said Jörg Heerlein, senior manager product marketing at Osram Opto Semiconductors.

The photodiode integrated in the sensor (4.7 mm x 2.5 mm x 0.9 mm) has an active surface of 1.3 mm x 1.3 mm. While highly sensitive to light, the diode also enables an extremely compact component to be produced with high linearity and excellent signal-to-noise ratio.

The infrared LED can also be used in combination with the photodiode as a proximity sensor to start or stop the measurement automatically as soon as the sensor touches or is removed from the skin. The integrated optical barrier prevents crosstalk from the three LEDs to the photodiode and therefore corruption of the optical signal or the entire measurement.

The SFH 7050 will be presented at electronica 2014 (hall A3, booth 110) in Munich from November 11 to 14, 2014.

SOURCE: Osram Opto Semiconductors; http://www.osram-os.com/osram_os/en/press/press-releases/ir-devices-and-laser-diodes/2014/compact-osram-sensor-improves-fitness-monitoring/index.jsp?search_result=%2fosram_os%2fen%2fpress%2fpress-releases%2findex.jsp%3faction%3ddosearch

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.