Nanoscale diamond photonic-crystal cavities store, connect quantum memories

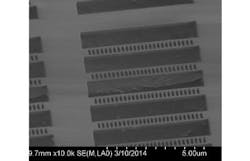

One-dimensional photonic-crystal (PC) cavities made of diamond that contain one or more nitrogen vacancies (NVs) in the cavity can store quantum digital information at room temperature in the form of electron spin, which can then be read out via photon emission enhanced by the cavity's high quality (Q) factor.

Now, researchers from the Massachusetts Institute of Technology (MIT; Cambridge, MA) and the U.S. Department of Energy's (DOE) Brookhaven National Laboratory (Upton, NY) have demonstrated such a device with a spin-coherence time (how long the memory encoded in the electron spin state lasts) of more than 200 µs, which is long time in the context of the rate at which computational operations take place.1 A long coherence time is essential for quantum computing systems and long-range cryptographic networks.

"Our research demonstrates a technique to extend the storage time of quantum memories in solids that are efficiently coupled to photons, which is essential to scaling up such quantum memories for functional quantum computing systems and networks," said MIT's Dirk Englund, who led the research. Scientists at the Center for Functional Nanomaterials (CFN), a DOE Office of Science User Facility at Brookhaven Lab, helped to fabricate and characterize the materials.

The Q of the Brookhaven/MIT device is about 10,000. The devices' performance was characterized in part using optical microscopy in a magnetic field at CFN, performed by CFN staff scientist Mircea Cotlet, Luozhou Li, and Edward Chen, who is also a graduate student studying under the guidance of Englund at MIT.

"Coupling the NV centers with these optical resonator cavities seemed to preserve the NV spin coherence time -- the duration of the memory," Cotlet says.

Adds Englund: "These methods have given us a great starting point for translating information between the spin states of the electrons among multiple NV centers. These results are an important part of validating the scientific promise of NV-cavity systems for quantum networking."

"The transferred hard-mask lithography technique that we have developed in this work would benefit most unconventional substrates that aren't suitable for typical high-resolution patterning by electron beam lithography," says Li. "In our case, we overcame the problem that hundred-nanometer-thick diamond membranes are too small and too uneven."

Source: http://www.bnl.gov/newsroom/news.php?a=11695

REFERENCE:

1. Luozhou Li et al., Nature Communications (2015); doi: 10.1038/ncomms7173

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.