220 gallium nitride MOCVD reactors to be installed in 2015 for LED production

LEDs as a business are growing rapidly in China, spurring purchase of the high-unit-cost capital equipment needed for LED fabrication. Due to the aggressive expansion plans of some Chinese LED companies, 220 metal-organic chemical-vapor-deposition (MOCVD) gallium nitride (GaN) reactors will be installed in 2015, according to the latest data in the IHS LED Intelligence Service. (MOCVD reactors are used to deposit GaN-based epitaxial films on substrates such as sapphire, silicon, or GaN, providing the LED's light-emitting structure.)

This new capacity expansion is slightly different from what happened several years ago, when large numbers of LED companies in China purchased government-subsidized tools, says IHS.

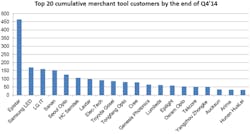

IHS forecasts that this year only large and publicly traded companies will purchase MOCVD phase epitaxy tools. The table below shows the largest 20 MOCVD customers as of the end of 2014: eight of them were Chinese companies and three of those companies -- Sanan, HC Semitek, and Aucksun -- have announced expansion plans for 2015.

Most of the new reactors purchased in 2015 will be new-generation tools, providing double capacity per reactor. Sanan is projected to lead in 2-in.-equivalent wafer-capacity share by the end of 2015, although Epistar would still own the largest number of MOCVD tools. The largest three Chinese companies will achieve a combined market share of 27% in 2015.

The large number of MOCVD tool shipments will result in a 28% increase in the level of excess supply in the LED market, according to IHS.

For more info, see https://technology.ihs.com/Services/467369/led-intelligence-service

Source: Alice Tao, senior market analyst, IHS