He-Ne lasers meet metrology challenges at PTB

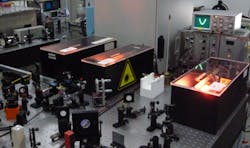

Figure. PTB measuring station for laser wavelength calibration by three iodine stabilized He-Ne gas lasers.

In recent years, the laser diode has replaced the Helium-Neon (He-Ne) gas laser in many high-volume applications such as barcode scanning, marking, and aligning. Yet as the He-Ne laser has ceased to be a high-volume product, it has become the preferred laser for specific high-value applications, including precision measuring applications in interferometers and spectrometers. The applications require rigorous mode and frequency stability--as well as resistance to magnetic fields.

LASOS (Jena, Germany) says it has responded to this changing market by investing in a new He-Ne laser manufacturing facility to produce both customized and standardized products. The company recently developed a custom He-Ne laser tube for Germany’s National Metrology Institute, the Physikalisch-Technische Bundesanstalt (PTB) in Braunschweig. The tube--LGR 7660 BF01—is now part of the ultra-precise interferometers of PTB.

PTB notes that the design of this laser dates from the 1970s and its reliability and stability have been optimized to current standards. The lasers contain an iodine cell of 10 cm length and a special He-Ne tube with Brewster windows approximately 25 cm long. The laser cavity is 37 cm long; the Zerodur rods maintain the distance between the mirrors.

Related article: Interferometry: Time in a fiber

Figure. Iodine stabilized lasers at PTB. The cavity mirror mounts are kept apart by three Zerodur rods. The iodine cell is seen in the foreground, the LASOS laser tube at the rear.

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.