Spectroscopic studies on ITER fusion reactor walls use Andor ICCD camera

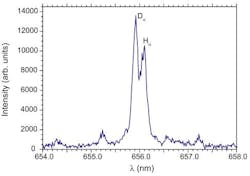

| An ICCD camera made by Andor is used in a laser-induced-breakdown spectroscopy (LIBS) test to be used on ITER's reactor walls. Here, it resolves the hydrogen and deuterium lines, helping to show the deuterium content of the coatings on the walls. (Image: Andor) |

To be completed by 2020, the ITER tokomak nuclear-fusion reactor being built in Saint-Paul-lès-Durance, France is the first fusion reactor expected to produce more energy than needed to run it. However, the fusion process will indirectly lead to the build-up of thick deposits of material layers on the reactor walls; the ITER engineers need to know how fast the deposits are growing, as well as their chemical composition, so that the maintenance of the reactor can be better planned and made more efficient with minimum impact on operation time.

A research team from the VTT Technical Research Centre of Finland (Espoo, Finland), the University of Tartu (Tartu, Estonia), INFLPR (Bucharest, Romania), and the Max-Planck-Institut für Plasmaphysik (Garching, Germany) has developed and tested a laser-induced-breakdown spectroscopy (LIBS) method for noninvasively measuring the composition of the layers, including specific beryllium-tungsten mixtures, for the first time. The technique uses an iStar ICCD camera made by Andor (Belfast, Ireland).

Noninvasive testing

"Shutting down any nuclear reactor is an expensive exercise, so a noninvasive diagnostics technique that maximizes service intervals has the potential for massive savings," says Antti Hakola, senior scientist at the VTT Technical Research Centre. "Our LIBS experiments are important as they show that the composition of the deposits as well as their thickness can be determined without taking any components out of the reactor. In addition, this is the first time that beryllium samples, which are very significant for fusion applications, have been analyzed and we now know their ablation characteristics."

Studying the depth profiles of the coatings revealed that coating removal rates depended on deuterium content as well as the thickness and makeup of the coatings.

"We compared products from a number of manufacturers before choosing the Andor SR-750 spectrograph and Andor iStar 340T intensified CCD (ICCD) camera," adds Hakola. "The key for us was the very fast (nanosecond) and precise (picosecond) temporal resolution as our main criteria were to ensure fast triggering, that the width and delay of the recording gate can be flexibly changed, even to a subnanosecond regime, and that the spectral resolution would be high (less than 0.05 nm). The spectrometer has proved an utterly reliable tool and the Andor software has also been helpful, particularly in obtaining kinetic series of how spectral lines evolve as the number of laser pulses increases."

For more info on Andor's ICCD cameras, see http://www.andor.com/scientific-cameras/istar-iccd-camera-series

Source: http://www.truepr.co.uk/news/at/PR49/001.asp?4836691-786031-333477-472022

REFERENCE:

1. J. Karhunen et al., Physica Scripta (2014); 2014(T159):014067. doi: 10.1088/0031-8949/2014/T159/014067