PG&O and SCHOTT team up on dark-energy telescope mirror project

Glass, optics, and optical coatings company Precision Glass & Optics (PG&O; Santa Ana, CA) has teamed up with SCHOTT North America (Duryea, PA) by selecting SCHOTT BOROFLOAT 33 glass for the Hobby-Eberly Dark Energy Experiment (HETDEX) mirrors project at Texas A&M (College Station, TX) and University of Texas, Austin. The telescope was designed to measure dark energy in outer space.

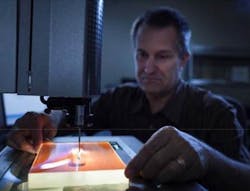

According to Dan Bukaty, Jr., president of PG&O, "BOROFLOAT was a great choice because of its low thermal expansion characteristics, excellent optical properties, and its relatively low cost, when compared to other optical materials. Specifications for optical mirrors are extremely demanding because even slight deviations can have a significant impact on the outcome of specific performance. The specialty optical mirrors used in the 150 spectrographs of the Visible Integral Field Replicable Unit Spectrographs (VIRUS) unit were carefully fabricated and coated in our Southern California facility. It was an exciting application for PG&O, and happily, a very successful project."

For more than 30 years, PG&O says it has provided affordable, high-volume precision optics, assemblies, and custom optical solutions for a wide variety of industries. With a 72 inch state-of-the-art coating chamber and a large, in-house glass substrates inventory, PG&O also provides quick turnaround on a wide array of flats, prisms, and beamsplitters. Applications include astronomy, medical, display, imaging, projection, defense, aerospace, scanning, and industrial instrumentation.

SOURCE: PG&O; http://www.pgo.com/pdf/6-15-15PG&O%20andSCHOTT_Team_Up_%20onOpticalMirrorsProject.pdf