I'm pretty sure that I have no interest in wearing a shirt laminated with a form-fitting LED display, even if it could give me useful information about my health or surroundings. Still, the opportunity to change my mind may not be far in the future.

Researchers in Belgium have been demonstrating the world’s first stretchable and conformable thin-film transistor (TFT) driven LED display laminated into textiles. Wearable devices such as healthcare monitors and activity trackers are already ubiquitous, but they remain separate devices. Integrated into our clothing, perhaps people would use them more, allowing more data to be collected and fitness and health better monitored—at least that is the researchers' hope.

To make the displays, small LEDs are mounted on an amorphous indium-gallium-zinc oxide (a-IGZO) TFT backplane that employs a two-transistor and one capacitor (2T-1C) pixel engine to drive the LEDs. These displays offer higher pitch and increased average brightness. A presentation of the technology at the International Meeting on Information Display (IMID) in Korea featured a 32 x 32 pixel demonstrator with a resolution of 13 pixels per inch (ppi) and average brightness above 200 candelas per square meter (cd/m2).

The LED displays are fabricated on a polyimide substrate and encapsulated in rubber, allowing the displays to be laminated in to textiles that can be washed. Importantly, the technology uses fabrication steps that are known to the manufacturing industry, which should make for rapid improvements toward cost-effective production.

The display was developed by imec (Leuven, Belgium); CMST, which is imec’s associated lab at Ghent University; and the Holst Centre (Flanders, Belgium), an independent R&D center set up by TNO (The Netherlands) and imec that develops technologies for flexible electronics, wearable health solutions, and perceptive systems for the internet of things.

In 2012, researchers at Philips Research in Einhoven wrote an article for Laser Focus World summarizing work on flexible OLEDs and optical fiber for "wearable photonics". It identifies some of the companies already making a fashion statement (eg, Lumigram in France) and explains a bit of where this field is headed: Smart photonic textiles begin to weave their magic!

Makers of fitness trackers like Fitbit must surely be taking note.

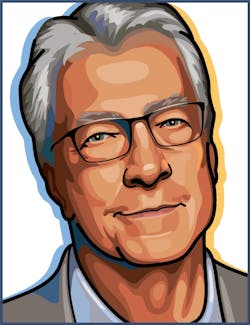

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.