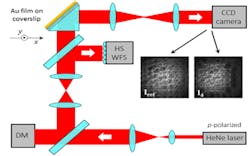

| The optical setup (DM = deformable mirror; HS WFS = Hartmann–Shack wavefront sensor, which the setup includes for comparison). (Image: OSA) |

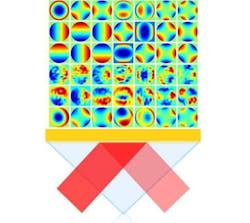

Using quasiparticles practically The sensor technology is based on a curious phenomenon: a quasiparticle that emerges when light waves couple with electron oscillations at certain types of solid surfaces. By measuring how efficiently incoming light creates these quasiparticles, the researchers are able to derive previously undetectable distortions in the wavefronts. Based on attenuated total internal reflection, the technique sees wavefront slopes as intensity differences across the beam produced by surface-plasmon polariton (SPP) excitation at the surface of a gold film. The result (a map of wavelength slope) is integrated to produce the wavefront shape.

(Image: OSA)

The resonance behavior of the SPP quasiparticles responds to even extremely small-scale wavefront distortions. SPPs arise when a wavefront meets an electrically conducting surface at a specific angle; at the point where they interact, electrons oscillate, forming a wave-like pulse that travels across the surface. Any changes in that angle, as would occur from a distortion in the wavefront, would affect the way the SPPs are formed. This then directly effects how much light is reflected back from the surface.

It is this change in reflected intensity that the researchers measure. To fully reconstruct the wavefront, the system requires two separate measurements made at 90º to one another, which are then integrated to produce the wavefront. The speed of the measurement is only limited by the speed of the cameras.

The researchers are working to overcome two limitations in the current setup. The first is the requirement for simultaneous measurement of wavefront changes with two cameras. The second is improving the method by which the SPPs are excited on the surface of the gold film.

Source: OSA

REFERENCE:

1. Brian Vohnsen and Denise Valente, Optica, Vol. 2, Issue 12, pp. 1024-1027 (2015); https://www.osapublishing.org/optica/fulltext.cfm?uri=optica-2-12-1024&id=333151