Adaptive LED headlights to enhance visibility while driving

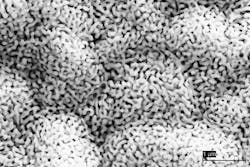

(Figure. To control each point of light independently a gold nano-sponge establishes the contact between each individual pixels and the driver chip. The nanoporous gold structure compresses like a real sponge and can be precisely adapted to the topography of the component. Courtesy Fraunhofer IZM.)

Researchers at the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin have collaborated with Infineon, Osram, Hella, and Daimler on the µAFS project to develop an LED-based, adaptive headlight system. The high-resolution illumination system has more than 1,000 LED pixels, offers considerably more options for precise light distribution than previous solutions, and is energy efficient.

The headlight will enhance safety by allowing permanent high beam, is less blinding to other road users, and makes it possible to alter the light distribution according to need such as turns in the road, oncoming traffic, and the distance and position of other road users. Only the pixels that are needed at the moment are turned on, which is usually about 30% of the total available light output of the entire system.

According to Hermann Oppermann, Group Manager in the Department of Wafer Level System Integration at the IZM, "We have been able to solidly connect four LED chips having 256 pixel each with the driver electronics chip. Because of this high resolution, we can control the light distribution to the smallest detail."

Researchers from the IZM were responsible for establishing contact between the individual pixels and the driver chip to control each point of light independently. "With a pixel size of only 125 microns, that is not an easy task. The connections have to be sturdy, and we need good thermal contact to ensure sufficient cooling of the chip," Oppermann explains.

The Berlin researchers have been pursuing two different approaches: In the first variant, a gold-tin alloy is applied in a pattern onto the chip. The technology is well established in the field of optoelectronics. Such fine grid structures with intermediate distances as small as 15 microns previously have not been possible. In the second approach, the researchers are working with a gold nano-sponge (see Figure).

Source:Fraunhofer IZM

Conard Holton

Conard Holton has 25 years of science and technology editing and writing experience. He was formerly a staff member and consultant for government agencies such as the New York State Energy Research and Development Authority and the International Atomic Energy Agency, and engineering companies such as Bechtel. He joined Laser Focus World in 1997 as senior editor, becoming editor in chief of WDM Solutions, which he founded in 1999. In 2003 he joined Vision Systems Design as editor in chief, while continuing as contributing editor at Laser Focus World. Conard became editor in chief of Laser Focus World in August 2011, a role in which he served through August 2018. He then served as Editor at Large for Laser Focus World and Co-Chair of the Lasers & Photonics Marketplace Seminar from August 2018 through January 2022. He received his B.A. from the University of Pennsylvania, with additional studies at the Colorado School of Mines and Medill School of Journalism at Northwestern University.