Wavefront sensors designed for LIGO now being used in commercial metrology

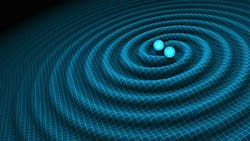

The University of Adelaide developed highly sensitive Hartmann wavefront sensors in South Australia for the LIGO detectors used to directly detect cosmic gravitational waves, which made global headlines. Although not used, the university also developed high-powered lasers for the project that, although not used for LIGO, are now being modified for potential application in the defense, oil and gas, and wind technology industries.

RELATED ARTICLE: Optical wavefront sensor samples wavefronts at a nanometric resolution

The basic concept of the Hartmann wavefront sensor has been around for a long time and was initially used to characterize mirrors for optical scientific telescopes but languished as the optical astronomy community became more interested in Shack-Hartmann wavefront sensors. But University of Adelaide (Adelaide, SA, Australia) head of physics associate professor Peter Veitch said the interesting part about his highly sensitive Hartmann sensors was their ability to perform at a variety of different optical wavelengths.

"If you look through a pair of spectacles you’ll see that the light coming from an object is adjusted, or distorted so that when it gets to your eye you can see it clearly,” he said. "But with the Hartmann sensor it can not only look at what the optical system—the lens in this case—does to visible light, it can also work in the infrared, the near-infrared, the mid-infrared, the far infrared and even down in the UV. That's a capability that is not available currently and that's why we're going to try to commercialise it."

There is a wide range of potential applications for the sensors. "It's a metrology tool that is very important for any state-of-the-art optical, laser physics, photonic application," said Veitch. "They might even be useful in the semi-conductive industry for measuring the flatness of silicon wafers before you deposit structures on them—there are a variety of applications and really it's a matter of trying to come up with a product that will be attractive to industry."

Veitch said the Hartmann sensors' role on the LIGO detector was to measure distortion inside the laser interferometers. He said distortion was caused when laser beams passed through the mirrors inside it and likened the effect to a mirage in the distance on a road on a hot day.

"When these laser beams pass through the mirrors within the interferometer part of it is absorbed so a bit of the mirror gets hot … the laser beam creates a temperature gradient and the temperature gradient distorts the laser beam," said Veith. "The problem was that these mirrors were buried 10 or 15 metres inside this vacuum system—you can't see them. It turns out that the Hartmann sensor is a factor of 30 better than any other competing sensor in the world and it can be used to measure this distortion buried inside this vacuum system, which none of the other sensors can."

SOURCE: The Lead South Australia; http://www.theleadsouthaustralia.com.au/industries/research-development/sensors-used-to-unlock-secrets-of-the-universe-to-be-commercialised/

About the Author

Gail Overton

Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.