Researchers from the University of California, Santa Barbara (UCSB), the U.S. Naval Research Laboratory (NRL; Washington, DC), and the University of Wisconsin, Madison have built the first quantum-cascade laser (QCL) on silicon (Si). The new device may have applications that span from chemical-bond spectroscopy and gas sensing to astronomy and free-space communications.

Integrating lasers directly on Si chips is challenging, but it is much more efficient and compact than coupling external laser light onto the chips. The indirect bandgap of Si makes it difficult to build a laser out of Si, but diode lasers can be built with III-V semiconductor materials such as indium phosphide (InP) or gallium arsenide (GaAs). By directly bonding a III-V layer on top of the Si wafer and then using the III-V layers to generate gain for the laser, this same group has integrated a multiple-quantum-well laser on Si that operates at a 2 µm wavelength. Limitations in diode lasers prevent going to longer wavelengths where there are many more applications, so the group turned their attention to using QCLs instead.

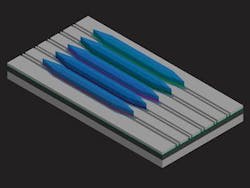

Silicon-on-nitride-on-insulator (SONOI) waveguides

Building a QCL on Si was a challenging task made more difficult by the fact that silicon dioxide (SiO2) becomes heavily absorptive at longer wavelengths in the mid-IR. "This meant that not only did we have to build a different type of laser on Si, we had to build a different Si waveguide too," says lead researcher Alexander Spott of the University of California, Santa Barbara. "We built a type of waveguide called a SONOI (silicon-on-nitride-on-insulator) waveguide, which uses a layer of silicon nitride (SiN) underneath the Si waveguide, rather than just SiO2."

The breakthrough could lead to several applications, Spott explains. "Traditionally, Si photonic devices operate at near-IR wavelengths, with applications in data transmission and telecommunications. However, there is emerging research interest in building these silicon photonic devices for longer mid-IR wavelengths for sensing and detection applications such as chemical-bond spectroscopy, gas sensing, astronomy, oceanographic sensing, thermal imaging, explosive detection, and free-space communications."

The next step for the team is to improve the heat dissipation to improve the performance of these QCLs and to allow them to make continuous-wave QCLs on Si. "We generally hope to improve the design to get higher powers and efficiency," Spott says. "This brings us closer to building fully integrated mid-IR devices on a Si chip, such as spectrometers or gas sensors. Silicon is inexpensive, the fabrication can be scaled up to significantly reduce the cost of individual chips, and many small devices can be built on the same Si chip – for example multiple different types of sensors operating at different mid-IR wavelengths."

Presentation at CLEO

The presentation "Quantum Cascade Laser on Silicon at 4.8 μm," by Alexander Spott, Jon Peters, Michael Davenport, Eric Stanton, Charles Merritt, William Bewley, Igor Vurgaftman, Jerry Meyer, Jeremy Kirch, Luke Mawst, Dan Botez, and John Bowers will take place from 14:00 – 16:00, Thursday, 09 June 2016 at the Conference on Lasers and Electro-Optics (CLEO; June 5 to 10, 2016; San Jose, CA).

Source: The Optical Society

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.