A research group led by Masayoshi Higuchi, the leader of the Electronic Functional Macromolecules Group, Research Center for Functional Materials at the National Institute of Materials Science (NIMS; Ibaraki, Japan), part of the Japan Science and Technology Agency (JST), has developed new flexible display sheets that can be cut into any shape with scissors.

RELATED ARTICLE: Sheetlike microplasma arrays have many applications

Common displays (including liquid-crystal display or LCD and organic light-emitting diode or OLED displays) that can present information in a variety of forms, such as digital signage and wearable devices, are in demand. However, it is impossible to cut these conventional displays into various shapes because it is necessary to seal the contents of both LCDs and OLEDs as they are susceptible to water, oxygen, and other impurities. Moreover, since these displays require a continuous power supply to maintain their functions, they must be connected with a power source or a drive.

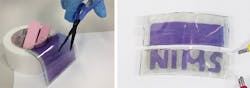

The research group developed display sheets that can be cut into any shape with scissors, using a polymer with electrochromic properties (organic/metal hybrid polymer). This polymer can be sprayed onto a flexible substrate to form a coating layer stable against moisture and oxygen. In addition, the new display requires only a few seconds of electrical input to switch visual information, and the display will last even after the power supply is discontinued.

In future studies, the group plans to increase the display area and make it capable of showing multiple colors. The study was conducted under the project "Ultrafast, ultralow-power, ultralarge-area electrochromism" (Masayoshi Higuchi, Research Director) in the research area "Innovative nano-electronics through interdisciplinary collaboration among material, device and system layers" (Takayasu Sakurai, Research Supervisor) as part of the Strategic Basic Research Programs (specifically the CREST program) sponsored by the JST.

SOURCE: JST National Institute for Materials Science; http://www.nims.go.jp/eng/news/press/2016/07/201607271.html

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.