Research team wins Rudolf Kingslake Award for SiC optical polishing method

Three researchers from the PLA University of Science and Technology (China) and two from the Research Center for Ultraprecision Science and Technology of Osaka University (Japan) will receive the Rudolf Kingslake Medal and Prize for 2015, to be presented at SPIE Optics + Photonics (August 28 - September 1, 2016; San Diego, CA) the evening of August 31st. The award is presented annually to the most noteworthy original paper published in the journal Optical Engineering.

Xinmin Shen, Qunzhang Tu, Guoliang Jiang, Hui Deng, and Kazuya Yamamura are the authors of the winning paper, "Mechanism analysis on finishing of reaction-sintered silicon carbide by combination of water vapor plasma oxidation and ceria slurry polishing," which was published in the May 2015 issue of Optical Engineering.

Reaction-sintered silicon carbide (RS-SiC) has robust mechanical, chemical, and thermal properties, so it has particular utility in space telescope systems and as ceramic material used for molds of glass lenses. Some of these properties include a low thermal expansion coefficient, high thermal conductivity, high radiation resistance, high specific stiffness, and impressive bending strength. But because of the compound's high level of hardness and chemical inertness, researchers have run into a few challenges—including the removal of RS-SiC post-application, which is very difficult using traditional mechanical and chemical techniques.

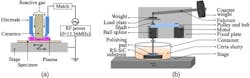

Smoothing and finishing of a RS-SiC surface has also proved to be a difficult task. The most promising and effective method so far involves a two-step process of water vapor plasma surface oxidation for 90 min. (see figure), followed by 40 min. of ceria slurry polishing on the oxidized layer shown in (b). Once an ultra-smooth surface has been achieved, the compound can be further developed and/or promoted for application in the fields of optics and ceramics.

The proposed technique is "a low-cost, efficient, and simple process, and the oxide layer is easy to machine, which can be an attractive technique for the machining of RS-SiC, RB-SiC, HP-SiC, and other SiC products by further development," the authors say.

The material is challenging to fabricate because of its high hardness, chemical durability, and grain structure, says Optical Engineering associate editor Jessica DeGroote Nelson (Optimax Systems; Ontario, NY). "The approach described by the authors combines precise chemical and mechanical processes utilizing plasma etching and cerium oxide polishing to provide ultrasmooth surfaces on RB-SiC," she says, noting that the material removal approach may also prove beneficial on other types of SiC in the future.

For full details of the work in Optical Engineering, please visit http://dx.doi.org/10.1117/1.oe.54.5.055106.