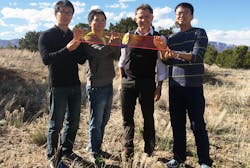

A team of Los Alamos National Laboratory (Los Alamos, NM) researchers is taking quantum-dot-based luminescent concentrators used in photovoltaic windows from the laboratory to the construction site, proving that the technology can be scaled up from palm-sized demonstration models to windows large enough to put in and power a building.1

Luminescent solar concentrators (LSCs) are light-management devices that can serve as large-area sunlight collectors for photovoltaic cells. An LSC consists of a slab of transparent glass or plastic impregnated or coated with highly emissive fluorophores. After absorbing solar light shining onto a larger-area face of the slab, LSC fluorophores re-emit photons at a lower energy; these photons are guided via total internal reflection to the device edges, where they are collected by photovoltaic cells.

Doctor-blade deposition technique

The Los Alamos team has created large LSC windows using the "doctor-blade" technique, used for depositing thin layers of a dot/polymer composite on top of commercial large-area glass slabs. The doctor-blade technique comes from the world of printing and uses a blade to wipe excess liquid material such as ink from a surface, leaving a thin, highly uniform film behind.

"The quantum dots used in LSC devices have been specially designed for the optimal performance as LSC fluorophores and to exhibit good compatibility with the polymer material that holds them on the surface of the window," says lead scientist Victor Klimov, who heads the Los Alamos Center for Advanced Solar Photophysics (CASP).

The Los Alamos LSCs use colloidal quantum dots to collect light because they have properties such as widely tunable absorption and emission spectra, nearly 100% emission efficiencies, and high photostability (they don’t break down in sunlight).

If the cost of an LSC is much lower than that of a photovoltaic cell of comparable surface area and the LSC efficiency is sufficiently high, then it is possible to considerably reduce the cost of producing solar electricity, Klimov says. "Semitransparent LSCs can also enable new types of devices such as solar or photovoltaic windows that could turn presently passive building facades into power-generation units."

The quantum dots used in this study are semiconductor spheres with a core of one material and a shell of another. Their absorption and emission spectra can be tuned almost independently by varying the size and/or composition of the core and the shell. This allows the emission spectrum to be tuned by the parameters of the dot’s core to below the onset of strong optical absorption, which is itself tuned by the parameters of the dot’s shell. As a result, loss of light due to self-absorption is greatly reduced.

Source: http://www.lanl.gov/discover/news-release-archive/2016/October/10.11-quantum-dot-solar-windows.php

REFERENCE:

1. Hongbo Li et al., Nature Energy (2016); doi: 10.1038/nenergy.2016.157

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.