Luminescent proteins provide color for ecological and cheap biodisplays

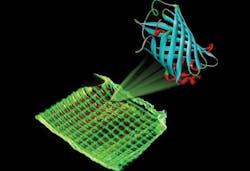

| Image of a color filter with green and red luminescent proteins printed on a microgrid structure. (Credit: Katharina Weber) |

Liquid crystal displays (LCDs), which are usually lit by inorganic white LEDs, have several inconveniences: the high cost of the color filters, limited brightness and contrast levels, and the difficulty of recycling materials used to make them. In response to these problems, scientists at the University of Erlangen-Nurnberg (Erlangen, Germany) have designed a new display made of natural materials: luminescent proteins, which the scientists say will enable, in the not too distant future, the manufacturing of these devices to be done ecologically and at a low cost.

The proteins are used in two parts of the display. The first component, in the display's backlighting, is a bio-LED emitting white light via different-colored luminescent proteins. "The proteins have a photoluminescence quantum yield of more than 75%," says Rubén D. Costa, one of the researchers. "High efficiency is guaranteed. In addition, they have a low emission bandwidth (30 to 50 nm), ensuring that high color quality and degradation does not produce significant color changes."

The second protein component in the display is the the color filter.1 Here, the proteins are stored in a polymeric matrix with micrometric resolution using a 3D printing technique, which enables them to maintain their luminescent properties and optimum stability.

"This color filter meets the necessary requirement to improve displays currently being used in terms of contrast and brightness within quality standards demanded across the market," says Costa. "This new material will allow for the development of energy-efficient biodisplays for TVs and mobile telephones with low production costs, high image quality, and ecological sustainability. Also, these filters are not rigid, allowing them to be used in devices which are flexible and light."

Source: http://www.alphagalileo.org/ViewItem.aspx?ItemId=171737&CultureCode=en

REFERENCE:

1. Lucas Niklaus et al., Advanced Functional Materials 27 (Issue 1), 3 January 2017; doi: 10.1002/adfm.201770002