Few people worldwide have a deep understanding of the details of the laser market. Arnold Mayer from Optech Consulting in Taegerwilen, Switzerland, is definitely one of them. And he has just announced his review of the market for laser sources and laser systems for material processing.

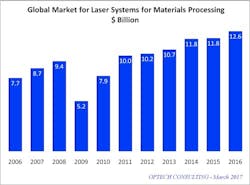

“2016 was one more good year for the laser industry,” Mayer said. “The revenue from industrial laser systems sales grew at a rate of 6.8%, even while other parts of the machine tool industry contracted. The global market for industrial laser systems reached a new record volume of $12.6 billion, which is solid progress compared to 2014 and 2015, when the market numbers remained almost unchanged.China up, ROW sideways

The increase was mainly due to China, where demand surged by nearly 20%. The manufacturing industry in the country continued to invest heavily into laser-based equipment despite the deteriorated economic environment. The demand for laser systems in Europe and North America trended sideward last year. Japan added a positive contribution resulting from the increased value of the Japanese yen.

Microelectronics market boosts laser sales

Laser macro processing systems accounted for 75% of the total market volume of $12.6 billion. Macro processing comprises cutting, welding, marking, and additive manufacturing. The market segment increased by 4.5% last year and outpaced the machine tool market, which contracted by 3% according to the VDW (German Machine Tool Builders’ Association; Frankfurt, Germany).

The automotive industry was a major driver of this growth, m substantial investments into high-power laser welding and cutting equipment.

With a market share of approximately 25%, microelectronics processing accounted for most of the rest of the market. This segment expanded by 15% in 2016, primarily because of the increased use of laser processes for the manufacturing of mobile electronic devices, displays, and semiconductors.

Fiber lasers still growing by 15%

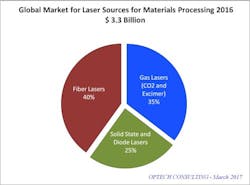

The global market for laser sources is counted separately from that of laser systems: the sources are the core devices used in laser systems, which in turn are sold to end customers who use these systems for materials processing in various industries.

Laser sources for materials processing accounted for $3.3 billion in 2016, up 5.4% versus the previous year. Fiber lasers now hold a 40% market share, ahead of gas lasers, represented by CO2 and excimer lasers (35%), and bulk solid state and diode lasers (25%). The demand for fiber lasers grew by 15% to $1.3 billion in 2016.

The market volume for bulk solid state lasers grew in the ultrashort-pulsed segment while it contracted in the segment of longer-pulsed products. Fiber lasers continued to take market share from high-power CO2 lasers as well as from bulk solid state lasers.In addition, CO2 lasers lost most of their market share in high-power cutting and welding, and their major applications now are marking and the processing of non-metals. The EUV business increasingly contributes to the CO2 laser market.

Excimer lasers are mainly used for microlithography and in display manufacturing. Market volume for excimers increased strongly in 2016, due to rising demand for flat panel display annealing.

Andreas Thoss | Contributing Editor, Germany

Andreas Thoss is the Managing Director of THOSS Media (Berlin) and has many years of experience in photonics-related research, publishing, marketing, and public relations. He worked with John Wiley & Sons until 2010, when he founded THOSS Media. In 2012, he founded the scientific journal Advanced Optical Technologies. His university research focused on ultrashort and ultra-intense laser pulses, and he holds several patents.