Optical birefringence mapping enables concrete stress testing

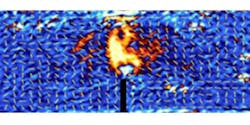

| An epoxy coating on a cement structure becomes birefringent under stress. The birefringence is optically measured across the structure, providing a map of stress. (Image: University of Leeds) |

Using an optical imaging system that senses the stress-induced birefringence of an epoxy coating placed on cement structures under load, researchers at the University of Leeds (Leeds, England) are mapping the strength of modern forms of concrete, giving the concrete industry a quantitative, 2D way to understand when a concrete structure could fracture.1

While the coating itself is not new, this research project was the first time it had been used to measure shear stress and assess the toughness of concrete against fractures. In the technique, polarized white light is projected onto the coated structure and the return light passed through a polarization analyzer on its way to a camera. The data is then processed, resulting in a visually informative image.

"There are other methods to measure stress and strain levels in the engineering sector, but we do not believe any of them can measure shear strain directly with high precision, which is most relevant to assess the failure strength of materials," says Joseph Antony, who led the study together with researchers at the University of Qatar. "The photonic method we developed can directly measure sheer strain, even on opaque materials. Until now, photonic and optical methods of measurement have only been associated with transparent materials."

The results using the new method compared favourably with conventional methods of stress testing, which have relied on combined experimental and numerical or analytical approaches.

Source: https://www.leeds.ac.uk/news/article/4077/high-tech_sensing_illuminates_concrete_stress_testing

REFERENCES:

1. S. Joseph Antony et al., Scientific Reports (2017); doi: 10.1038/s41598-017-04782-7