NASA's Mars 2020 rover will carry new SuperCam and other boosts to photonic capabilities

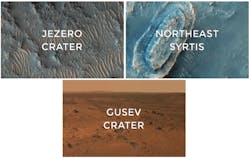

NASA's Mars 2020 space mission will carry and deploy a rover that looks a lot like the Curiosity rover now exploring the Gale Crater on Mars. As of today (Sept. 25, 2017), no site has yet been chosen for the Mars 2020 landing site, although three candidate sites currently exist (see above): Northeast Syrtis (a very ancient portion of Mars' surface), Jezero crater, (once home to an ancient Martian lake), and Columbia Hills (potentially home to an ancient hot spring, explored by NASA's Spirit rover).

While the Mars 2020 rover may appear to be a virtual copy of the Curiosity rover, its optics and photonics hardware are getting a significant upgrade.

For example, the existing Curiosity rover carries the ChemCam, which included a laser-induced breakdown spectroscopy (LIBS) system to remotely capture the chemical makeup of its surroundings. The pulse of infrared light fired by the LIBS system lasts only a few nanoseconds, but is energetic enough to vaporize rock at the spot it hits, creating temperatures of more than 8000°C.

As for 2020, exit the ChemCam—and enter the SuperCam. In addition to a faster LIBS system, the SuperCam for Mars 2020 will carry an entirely new conduction-cooled laser system to provide the nondestructive analysis capability of Raman spectroscopy, which is able to detect carbon-based signatures of organic materials.

Model of SuperCam already built

Together with the Centre National d'Etudes Spatiales (CNES; Paris, France) and The Research Institute in Astrophysics and Planetology (IRAP; Toulouse, France), the Thales Group (La Défense, France) is in the final stages of testing the compact SuperCam system that will eventually endure harsh Martian conditions. They have already built and tested a full representative model; the results of this research will be presented at the OSA Laser Congress (1-5 October 2017; Nagoya, Japan).

The upgraded LIBS oscillator uses a diode-pumped Nd:YAG crystal, as opposed to ChemCam's neodymium-doped potassium-gadolinium tungstate (Nd:KGW); the new laser provides longer bursts but requires new methods to ensure functionality over a large temperature range. Because Nd:YAG absorbs over a narrow range of frequencies to lase at a given temperature, the SuperCam will carry a multicolor stacked laser-diode source that can pump over a wide spectrum to account for a range in temperatures.

"This laser is running in burst mode, but with this laser we can do 1000 shots in one burst while the ChemCam laser was 10 times less," says Eric Durand, one of SuperCam's developers at Thales Group. "We longitudinally pump this laser with a stack that is broadband emitting so that when the temperature is changing, the Nd:YAG crystal is still absorbing the light and the laser can be used over at least 50 to 60 °C without temperature regulation."

Frequency doubling

Unlike Curiosity's LIBS-only functionality, the SuperCam will be able to switch between a LIBS mode and a Raman mode of lasing, a method that requires two different laser colors to excite and probe molecular vibration energies for its nondestructive chemical identification. The second color is produced by a nonlinear crystal that doubles the 1064 nm frequency used for LIBS measurements—which now will produce 10 times as many shots in each burst of the laser for faster sampling.

This second, 532 nm beam will allow Mars 2020 to detect molecular structures evident of organic matter, or evidence of past life. The new optical architecture required to produce the two operation modes, however, was not without its challenges: adding another complication to temperature control, the KTP crystal producing the frequency-doubled light required additional stabilization.

"The most difficult aspect was to achieve the temperature range also with the green wavelength because we have to keep the efficiency over the whole range, and it was only possible by heating a little the KTP crystal," says Durand.

The temperature stabilization required to keep the system aligned and working for either mode is difficult enough to achieve in a lab, but this system was designed to have the same stability while on the rover as it traverses the rocky Martian terrain. Moreover, it has to meet severe size and weight restrictions that come with space travel, and must stay free of contaminants that would destroy its components—a feat achieved by sealing the instrument with laser-welding.

Sources:

https://mars.nasa.gov/news/scientists-shortlist-three-landing-sites-for-mars-2020/

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.