Richard J. Saykally and Raphael Casaes

Pulses from a tunable laser recirculate in an optical cavity, increasing absorption path length and making possible high-sensitivity spectroscopic measurements.Over the past decade, cavity ringdown spectroscopy has emerged as a powerful technique for performing direct absorption measurements using pulsed lasers. Developed in 1988, cavity ringdown spectroscopy has since been used from the ultraviolet to the mid-infrared.1 In a typical ringdown experiment, a short laser pulse is injected into a cavity formed by two highly reflective mirrors (reflectivity greater than 99.99%), separated by a distance chosen to be large compared to the laser coherence length. Light exiting the cavity is monitored by a suitable detector.

Under these conditions, interference effects are negligible and the laser pulse can be viewed as a particle bouncing back and forth in the cavity (see Fig. 1). With a reflectivity R and cavity length L, the intensity of light in the cavity is given by a simple exponential function of the form

I = Ioe-t(1-R+A)c/L

where Io is the initial intensity, c is the speed of light, t is time, and A is the per-pass fractional losses due to some absorbing species in the cavity. Thus, by measuring the decay constant, it is simple to calculate the absorption by a sample present in the cavity. Because the decay constant is independent of the initial laser intensity, cavity ringdown spectroscopy is insensitive to laser shot-to-shot power fluctuations, allowing high-sensitivity (fractional absorptions of one part per million) absorption measurements to be made with pulsed lasers, which are easier to operate and have much greater spectral coverage than continuous-wave (CW) lasers.

Cavity ringdown spectroscopy matures

The first pulsed ringdown experiments were performed in the visible and ultraviolet regions of the spectrum. Cavity ringdown spectroscopy was used to study a variety of metal clusters and metal-containing molecules formed by laser ablation in supersonic beams. By using a dye laser to pump a hydrogen Raman shifter, University of California-Berkeley researchers were able to extend cavity ringdown spectroscopy into the mid-infrared.2 This new capability allowed scientists to study a variety of hydrogen-bonded clusters formed in molecular beams.

FIGURE 1. In the photon-bullet model of cavity ringdown spectroscopy, a laser pulse with small coherence length relative to the cavity length is injected into the cavity through one of the mirrors. A detector placed behind the other mirror monitors the light exiting the cavity. If the detector has a fast-enough response time, it will see individual laser pulses leaking out of the cavity separated in time by the cavity round trip time and with an exponentially decreasing intensity. In practice, infrared detectors cannot resolve the individual pulses; only the exponential envelope is observed.

The hydroxyl (OH) stretching bands of a variety of hydrogen oxide (H2O)n and deuterium oxide (D2O)n clusters were measured for n ranging from 2 to 6.3, 4 With the dye laser's 0.04-cm-1 resolution, the Berkeley group was able to measure rotationally resolved spectra of the water dimer, providing invaluable information for the development of an accurate water pair potential.5, 6 Infrared cavity ringdown also was used to measure the OH stretching bands of methanol, ethanol, and propanol clusters, giving insight into hydrogen bond cooperativity effects.7, 8

Attempts also were made to use the dye-laser-based infrared cavity ringdown spectrometer to study carbon clusters formed by laser ablation in supersonic beams. In theory, pulsed cavity ringdown spectroscopy is a better technique for studying these clusters than CW diode-laser infrared absorption spectroscopy because of the improved duty cycle inherent in the pulsed experiment. However, the limited resolution of the dye laser (1200-MHz linewidth versus 150 MHz for the carbon-cluster absorptions) effectively decreased the ringdown sensitivity by an order of magnitude. As a result, a new, pulsed infrared cavity ringdown spectrometer was recently built that is continuously tunable from 2.8 to 8 µm with a laser linewidth of 85 MHz.

Pulsed versus continuous wave

Several factors influenced the decision to continue using pulsed instead of CW lasers for high-resolution infrared cavity ringdown spectroscopy. First and foremost was the lack of CW lasers covering the entire mid-infrared. Lead-salt diode lasers are not continuously tunable, while color-center and quantum-cascade lasers have a limited tuning range. Furthermore, CW techniques are not well-suited for the study of transient species such as those formed in laser ablation sources.

In typical CW ringdown experiments, the cavity length is modulated such that the cavity sweeps over at least a full free-spectral range. When the cavity length is a multiple of half the laser wavelength, intensity quickly builds up in the cavity. This triggers an electro-optic modulator, which blocks the laser from entering the cavity, and the decay of light trapped in the cavity is monitored.9 This technique works very well for static-cell or flow-cell measurements; however, when used to study species formed in a molecular beam, the ringdown event has a timing jitter of approximately 100 µs relative to the molecular beam.10 This precludes the use of CW-based techniques for studies of species formed in laser ablation sources where the transit time is approximately 5 µs.

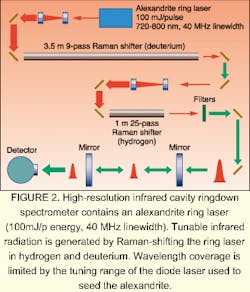

A high-resolution infrared cavity ringdown spectrometer developed by the Berkeley group is based on an injection-seeded alexandrite ring laser. This laser pumps a deuterium Raman shifter, which in turn pumps a hydrogen Raman shifter, the output of which is injected into the ringdown cavity (see Fig. 2).

The use of a high-resolution laser introduces some complications into the simple ringdown picture described above. Since the coherence length of the laser is longer than the cavity length, interference effects in the cavity become significant and the transverse mode structure of the laser in the ringdown cavity will depend on the laser frequency. Because different transverse modes sample different parts of the mirror, the per-pass losses of the empty cavity will vary as the laser is scanned over a cavity free spectral range. These baseline oscillations can be subtracted by measuring the per-pass losses of the empty cavity and subtracting that from the per-pass losses of the cavity with an absorber at each point in the scan. This can be conveniently done in laser ablation experiments since the cluster transit timeapproximately 5 µsis short compared to the ringdown time (the time it takes for the intensity to decrease to 1/e of its initial value), allowing the baseline losses to be subtracted for individual laser shots.

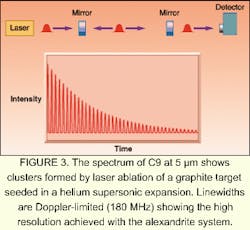

This new spectrometer has recently been used to measure the n6 asymmetric stretch of linear C9 at 5 µm (see Fig. 3); systematic searches for carbon clusters are being carried out in the 2000- to 1900-cm-1 range. The high sensitivity of cavity ringdown, combined with the high resolution of the alexandrite laser, make this spectrometer comparable to lead-salt diode and color-center laser spectrometers, with the added advantage of continuous coverage of the mid-infrared and the convenience and power of pulsed cavity ringdown for the study of transient species.

REFERENCES

- A. O'Keefe, D. A. G. Deacon, Rev. Sci. Instrum., 59, 2544 (1988).

- J. J. Scherer et al., Chem. Phys. Lett., 245, 273 (1995).

- J. B. Paul, C. P. Collier, R. J. Saykally, J. J. Scherer, A. O'Keefe, J. Physical Chem. A, 101, 5211 (1997).

- J. B. Paul, R. A. Provencal, C. Chapo, A. Pettersson, R. J. Saykally, J. Chem. Phys., 109, 10201 (1998).

- J. B. Paul, R. A. Provencal, R. J. Saykally, J. Phys. Chem. A, 102, 3279 (1998).

- R. S. Fellers, L. B. Braly, M. G. Brown, C. Leforestier, R. J. Saykally, Science, 284, 945 (1999).

- R. A. Provencal et al., J. Chem. Phys., 110, 4258 (1999).

- R. A. Provencal et al., J. Phys. Chem. A, 104, 1423 (2000).

- B. A. Paldus et al., Opt. Lett., 25, 666 (2000).

- M. Hippler, M. Quack, Chem. Phys. Lett., 314, 273 (1999).

RICHARD J. SAYKALLY is a professor and RAPHAEL CASAES a researcher at the University of California-Berkeley, Department of Chemistry, D31 Hildebrand Hall, Berkeley, CA 94720; e-mail: [email protected].