With the advent of easier-to-use, lower-cost vision systems, and with increasing awareness among manufacturers about the many benefits of these solutions—particularly increased quality—the use of vision systems is on the rise worldwide across many industries, including semiconductor, electronics, automotive, and pharmaceutical. For many people, however, the components of a vision system and the way in which they work together remain unclear.

Because the subject of machine vision can be intimidating, people in companies that might benefit substantially from implementing a vision system, but who remain in the dark about how such a system works, may choose not to implement one. An example illustrating one company's real-world inspection application helps to elucidate some common components of a typical vision system and how they work together, removing some of the mystery.

Choosing machine vision

Comact Optimisation Inc. (Boisbriand, Que., Canada) is a developer of sawmill equipment and plants that range from simple conveyors to automated production lines. For many years, Comact relied on human inspectors to help reduce overhead, decrease cutting errors, correctly classify wood, and optimize yields, all of which are keys to success in the highly competitive lumber industry.

Driven by the need for greater precision and speed nearly a decade ago, the company searched for an automated solution that would augment the efforts of human operators. The type of technology was irrelevant to Comact's engineers, as long as it could provide the desired speed and reliability. After identifying and testing several possible solutions, Comact began incorporating turnkey machine-vision systems into its sawmill machinery that came equipped with cameras. Now, nearly all of its equipment is outfitted with a vision system.

FIGURE 1. Based on laser-triangulation measurements, a monochrome machine-vision system (red object) at a sawmill determines the optimum cuts for a tree trunk.

While Comact has implemented several machine-vision configurations in various pieces of equipment, its most prevalent is a monochrome machine-vision system that provides precision identification of the shape of each tree trunk to optimize cutting operations in machinery used for the linear transport of the trunks (see Fig. 1). By implementing software that calculates parameters using a triangulation method and an optimizer, operators can determine how each trunk should be cut so that it yields the maximum amount of usable wood. Such optimization of the cutting operations cannot be achieved without the precision of machine vision.

Cameras

To begin the inspection, from 2 to 25 cameras snap images of each tree trunk. The characteristics of the cameras were chosen to satisfy several needs.

A high speed is required to keep pace with the rapid movement of the lumber through the identification machine and other equipment on the line. In any vision application, required frame rates (for example, 30, 60, or 120 frames per second, or FPS) should be clearly established when specifying a camera, as this affects the speed of the system and is critical to performance.

High-resolution and high-quality cameras are needed to provide the best possible images upon which to make accurate calculations and the resulting cuts. For applications that involve calculations, and those that require detection of very small features (for example, defects in electronics), cameras of 1k × 1k to 4k × 4k pixels are required. In other applications, such as those in which defects can be detected by the human eye but can be accomplished more quickly and reliably using machine vision, standard cameras are sufficient.

The price-versus-performance ratio often becomes a deciding choice in those applications that do not demand the highest possible resolution. For example, a camera with 1k × 1k resolution and a speed of 30 FPS costs an average of about $5,000, whereas a lower-resolution camera that runs at 30 FPS averages $500.

Robustness and low signal-to-noise ratio are both essential features in cameras used in harsh plant environments.

Lighting

Once an image is acquired, between 2 and 80 lasers perform the triangulation calculations. Lasers were chosen for this application because of their profiling capabilities. The lasers project multiple lines of light as the log comes down the arc, which assist the mill in determining the maximum amount of value that can be extracted from the log. By projecting a uniform line of illumination onto the trunk of the wood, the lasers provide precision data that is used to determine how many pieces of wood can be produced from each trunk.

Other commonly used light sources for machine-vision applications include ring lights, which, by illuminating an object or area of interest from the top down, help eliminate distortion; fiberoptic lighting, used to illuminate locations where normal lighting cannot penetrate (for example, within a dark object like a car motor); and backlight illumination, used to generate a contrast between the object and the background. Medical x-rays are a well-known example of backlight illumination.

Image acquisition, processing, and analysis

The image-acquisition board provided by Coreco Imaging to Comact accommodates up to four asynchronous cameras, allowing Comact to eliminate synchronization circuits that would be required with other boards. The hardware performs simultaneous acquisition of up to 40-MHz digitization per channel from up to four camera channels. Each channel has an analog-to-digital converter, synchronization circuitry, an anti-aliasing filter, input look-up tables, and the ability to respond to four independent trigger events. Buffer image data can be stored in local memory during heavy PCI (peripheral component interconnect) bus traffic to increase acquisition speed and host availability for processing.

A frame grabber must reliably convert video images from cameras into digital format at the required rate for each application. To enhance image quality and ensure the success of vision applications, some boards also offer features that compensate for poor lighting, poor optics, and poor presentation of the data from the camera to the frame grabber. These features include input signal conditioning, look-up tables, and histogram equalization.

In the Comact application, images are transferred from the image-acquisition board to a Pentium PC for processing and optimization. By relying on a PC-based architecture, Comact can achieve its performance goals with the flexibility and ease of interfacing offered by PCs.

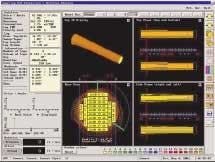

Although off-the-shelf image analysis and processing packages are readily available, Comact engineers chose to develop their own software based on the unique nature of the application. Their image analyzer detects the slices of the laser on the trunk and builds a 3-D shape based upon this data. The optimizer then determines what lumber sizes (for example, 2 × 3, 2 × 4, or 2 × 6) can be fit in the shape (see Fig. 2).

FIGURE 2. Vision-system software calculates the volume and shape of a log, then produces a map of optimum cuts.

The optimizer must also take into account the mechanical constraints of the tools, the cost of the finished products, and other parameters. The optimizer sends the results of its analysis to a programmable logic controller, which controls the machine equipment throughout the process (saw movement and other operations).

The resulting information about how to cut the log most optimally is then transmitted via Ethernet to a programmable robot system, which controls the mechanical equipment accordingly. Once cut, the lumber is graded by a separate vision system (see "Making the grade," above). This application of vision systems to lumber cutting is but one example of how the decreasing cost and increasing ease of use and interfacing of vision systems enables the practical industrial networking of vision and robotics systems.

YVON BOUCHARD is the director of systems architecture and PHILIP COLET is the vice president of worldwide sales and marketing for Coreco Imaging, 7075 Trans-Canada Hwy., St. Laurent, Que., Canada; email: [email protected].

Making the grade

Comact has also incorporated a machine-vision system into the company's new lumber grader. Using a 3-D scanner reading and a color vision system to detect such defects as rotten wood, knots, and cracks, the grader automatically determines the quality grade of each piece of cut timber (2 × 4s and other boards). Using machine vision in this application dramatically increases throughput and accurately grades the quality of the cut timber by providing faster, more-reliable inspections, which were previously performed by human operators.

High-frequency fluorescent tubes light each piece of wood. Eight line-scan cameras and eight frame grabbers acquire images of the wood in search of any defects that will affect the grade of each piece. The frame grabber is a single-slot video acquisition and pre-processing board for the PCI bus that has high-speed, high-quality image acquisition of up to 160 MB/sec and handles a variety of data formats. The speed of the frame grabber is crucial to the success of the application, which demands real-time acquisition and processing of images. In addition, because the board contains a driver to the line-scan camera, Comact saved the time and money involved in developing a driver from scratch.